HDPE Water Supply Pipe for Water Supply System

Send Inquiry

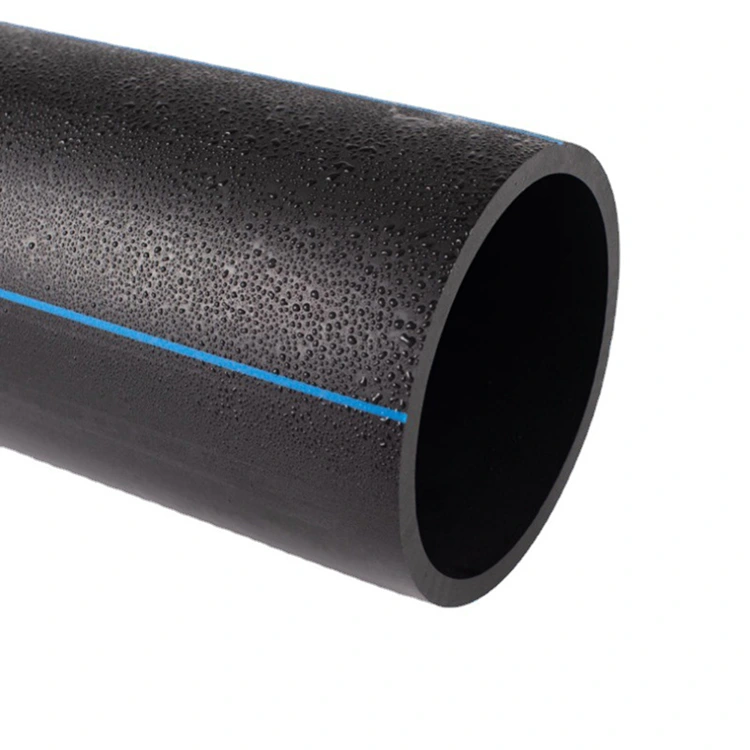

Durable HDPE Water Supply Pipe for Water Supply System

Company Introduction

The company focuses on the research of new materials and the supply of engineering pipelines. Its products have been applied in highways, tunnels, municipal networks, and farmland irrigation. Company Introduction

Over time, the company has worked alongside major contractors on a range of infrastructure projects. This cooperation has helped us refine our products for use in both domestic and overseas markets. Today, our solutions are recognized not only for their durability but also for their cost effectiveness in agriculture and construction projects worldwide.

Material Features and Advantages

In real project use, HDPE pipes have proved practical and reliable. The inner surface is smooth, so water passes through with less resistance and fewer deposits. Thanks to their light weight, the pipes are easier to move and fit on site, which reduces labor effort during installation and keeps maintenance needs lower later on.

The material also resists corrosion and a wide range of chemicals, which makes it suitable for use in demanding underground conditions. When joined with butt fusion or electrofusion methods, the pipe sections form tight, leak-proof connections, ensuring long-term service in irrigation, drainage, and water supply systems.

Application Scenarios

- Municipal water supply systems

- Underground distribution networks

- Agricultural irrigation projects

- Industrial water transportation

- Infrastructure construction such as roads and bridges

Product Features (Basic Info)

Material: High Density Polyethylene (HDPE)

Color: Black with Blue Stripes

Length: Customized, available in coils or straight lengths

Connection: Butt fusion, Electrofusion, Socket fusion

Standard: ISO4427 / GB/T13663

Working Pressure: PN6 – PN16

Size Range: 20mm – 1200mm

Technical Parameters

|

Nominal Diameter (mm) |

SDR |

Pressure Rating (PN) |

Wall Thickness (mm) |

Length |

|

20 |

SDR11 |

PN16 |

2.3 |

Coil 100m |

|

32 |

SDR11 |

PN16 |

3.0 |

Coil 100m |

|

63 |

SDR11 |

PN16 |

5.8 |

Straight 6m / 12m |

|

110 |

SDR17 |

PN10 |

6.6 |

Straight 6m / 12m |

|

160 |

SDR17 |

PN10 |

9.5 |

Straight 6m / 12m |

|

225 |

SDR17 |

PN10 |

13.4 |

Straight 6m / 12m |