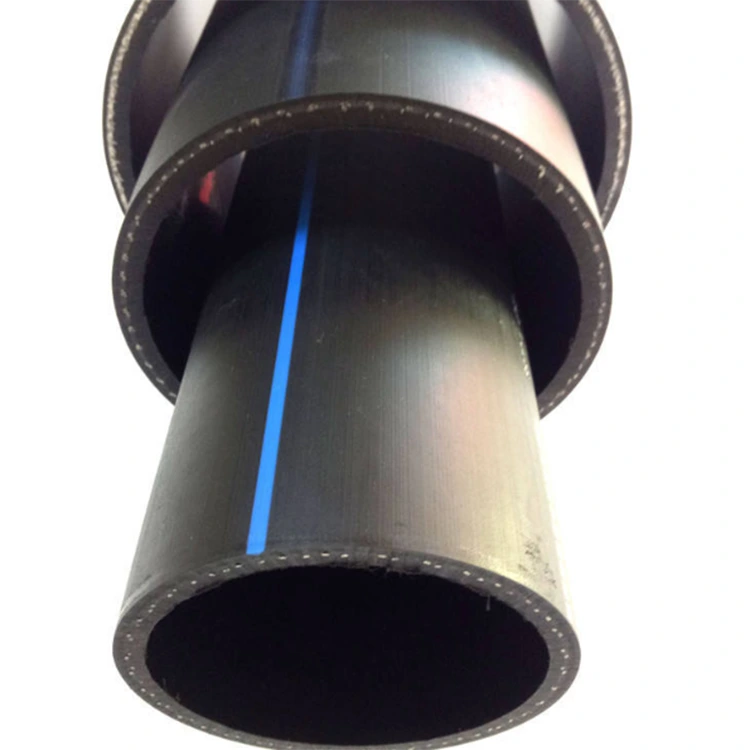

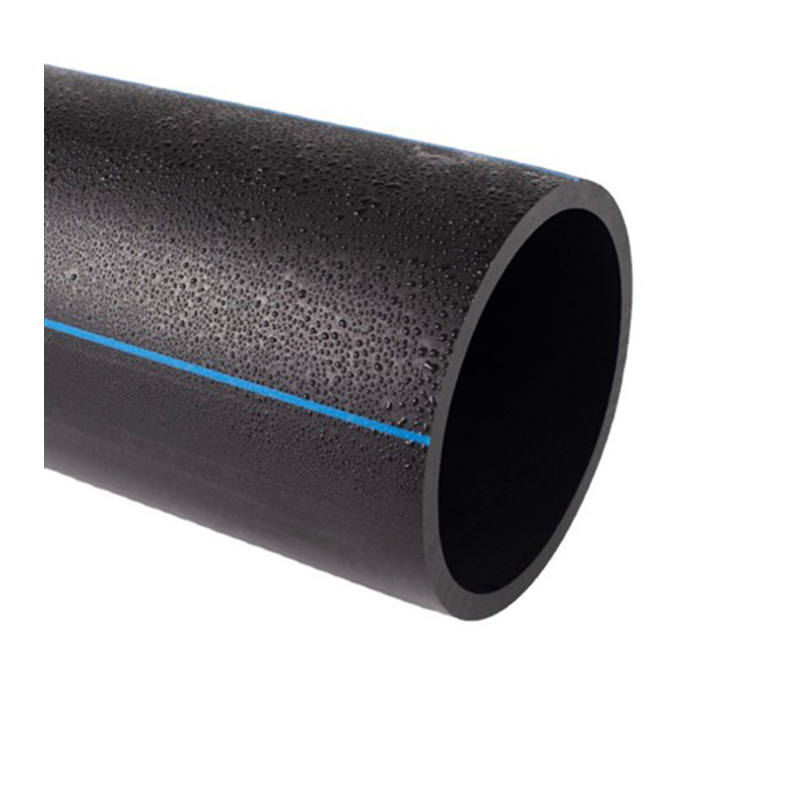

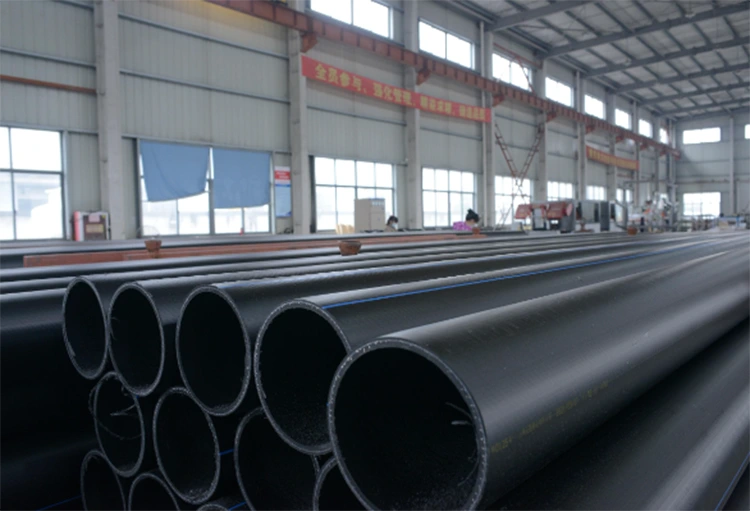

HDPE Steel Wire Reinforced PE Composite Pipes

Send Inquiry

HDPE Steel Wire Reinforced PE Composite Pipes Introduction

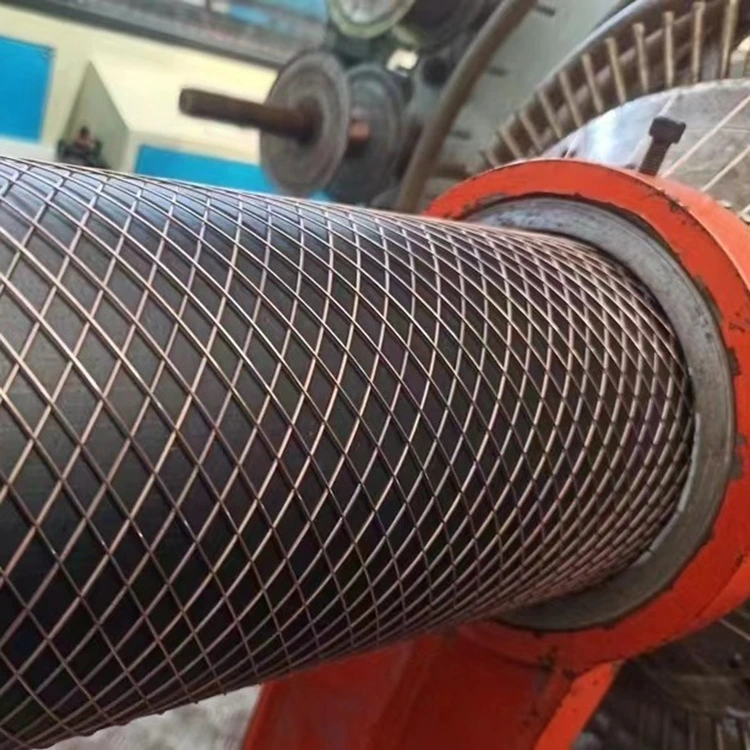

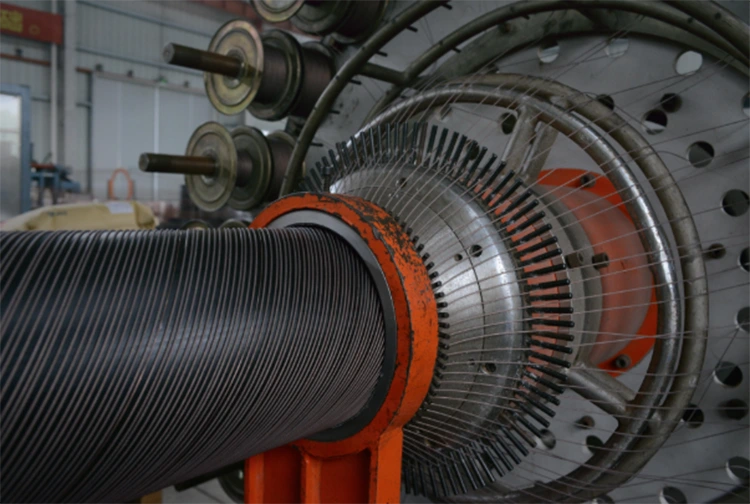

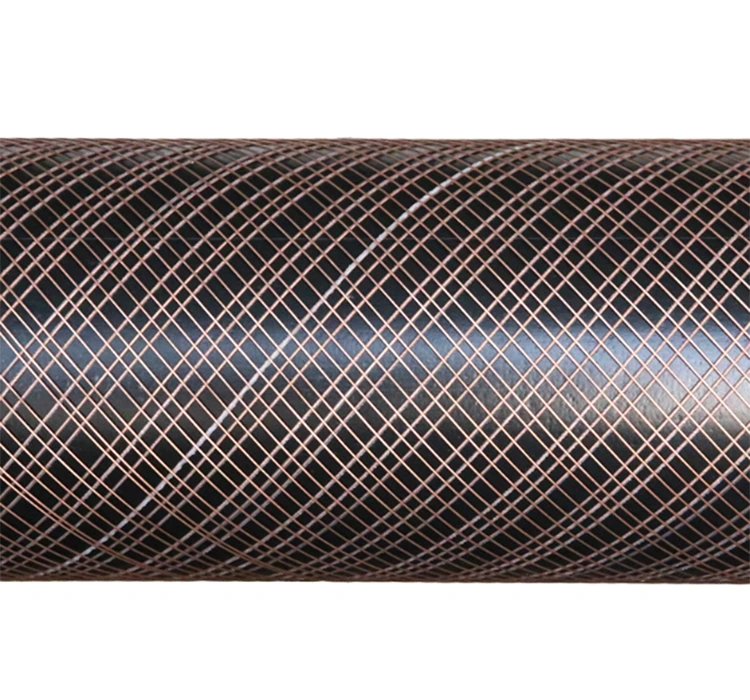

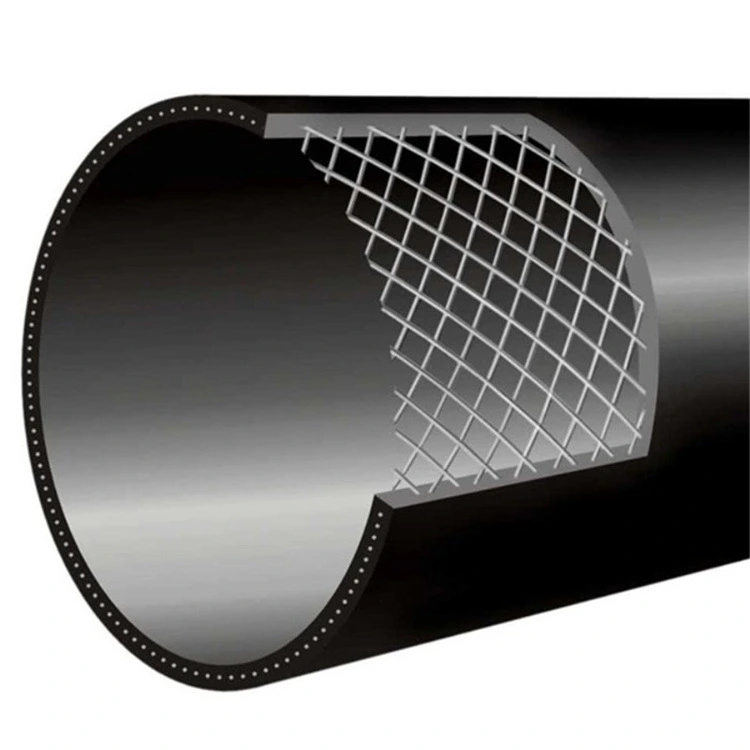

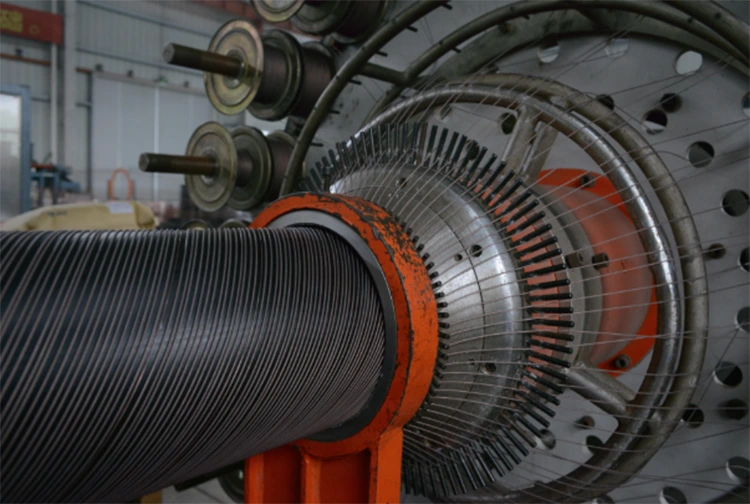

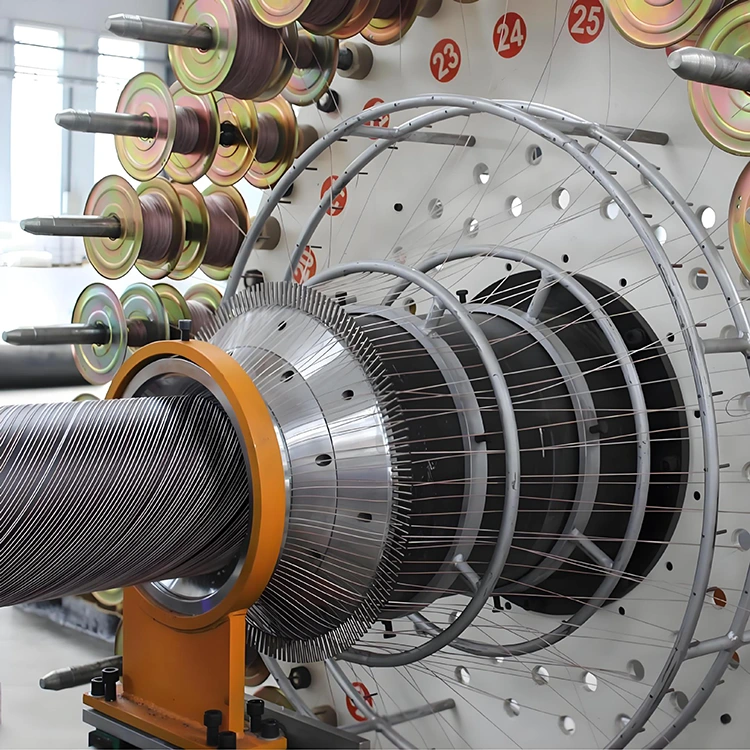

This advanced composite pipe features a high-strength steel wire mesh skeleton fused with thermoplastic polyethylene (HDPE). The cross-galvanized steel wire reinforcement is fully encapsulated within the HDPE matrix using a modified bonding resin, creating an excellent bond and combining the advantages of both materials.

Request a quote for your composite pipe now!

Parameter (Specification)

|

Nominal Outer Diameter(mm) |

PN 1.0 Mpa |

PN 1.6 Mpa |

|

50 |

- |

● |

|

63 |

- |

● |

|

75 |

- |

● |

|

90 |

- |

● |

|

110 |

● |

● |

|

125 |

● |

● |

|

160 |

● |

● |

|

200 |

● |

● |

|

225 |

● |

● |

|

250 |

● |

● |

|

315 |

● |

● |

|

355 |

● |

● |

|

400 |

● |

● |

|

500 |

● |

● |

|

630 |

● |

- |

Feature And Application

Key Features:

1.Eliminates Stress Cracking - The steel-plastic composite structure prevents rapid stress cracking common in plastic pipes

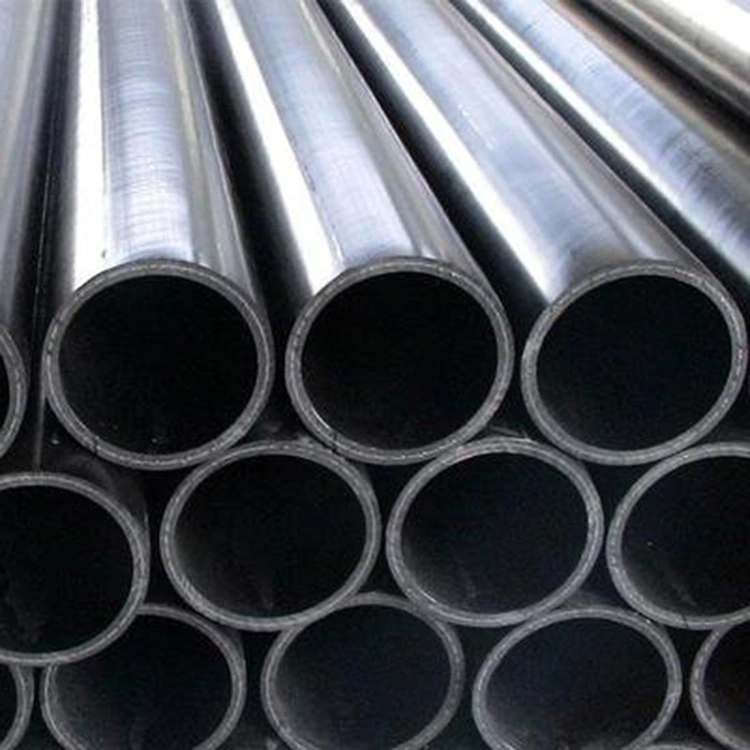

2.Enhanced Strength -This kind of black hdpe pipes have superior rigidity and impact resistance vs standard plastic pipes, with steel-like low thermal expansion

3.Lightweight and Easy Installation - Features electrofusion joints with reliable axial strength and compatible fittings

4.Dual Corrosion Protection - Maintains plastic's corrosion resistance with higher temperature tolerance

5.Integrated Structure - Steel mesh and HDPE layers form inseparable bond, preventing delamination

5.Smooth Interior -Our HDPE steel wire reinforced pipes 30% lower friction loss than steel pipes with scale-resistant surface

6.Customizable Specifications - Adjustable wire diameter and plastic thickness for different pressure ratings

Application Fields:

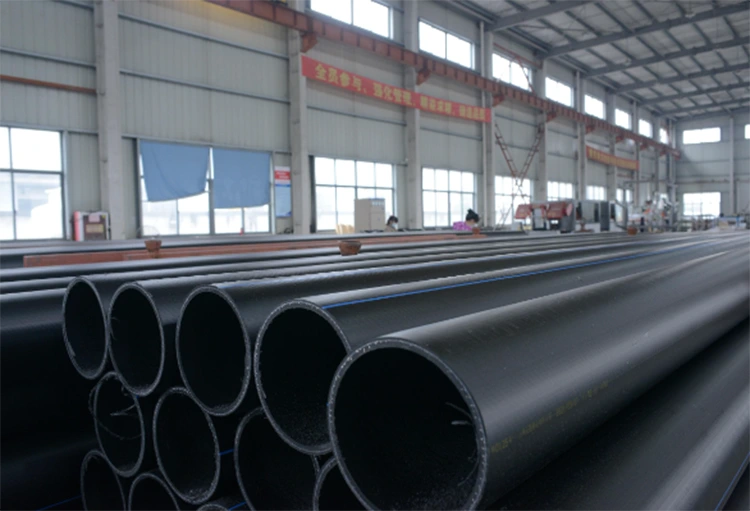

1.Long-Distance High-Pressure Water Supply Projects

2.Our HDPE steel wire reinforced pipes used in buried rainwater, drainage and sewage systems.

3.Transportand Discharge Systems for Corrosive Chemical Solvents

4.Slurry Transportand Wastewater Discharge in Mining Operations

5.Agricultural Irrigation Pipelines

6.Oil and Gas Transportation

7.Firefighting High-Pressure Water Supply Pipe