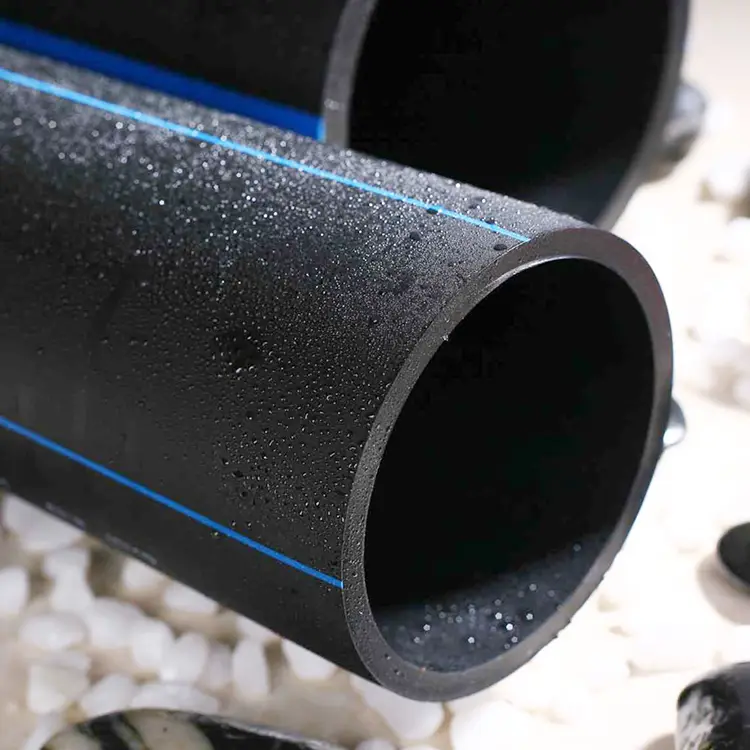

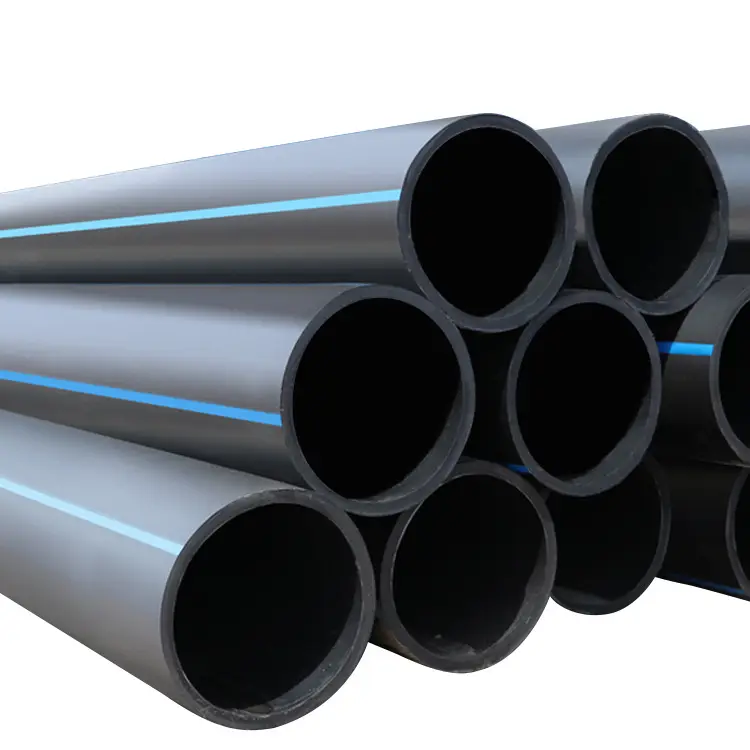

HDPE Water Supply Pipe

Send Inquiry

Introduction

Our HDPE pipes offer superior strength, flexibility, and corrosion resistance, making them ideal for diverse applications,including water supply, drainage, mining, and cable protection. Designed for durability, they feature heat-fused joints, UV stability, and exceptional abrasion resistance,lasting over 50 years even in harsh environments. Lightweight and easy to install using trench or trenchless methods, our HDPE pipes deliver reliable performance with low maintenance, reduced pressure loss, and cost-efficient operation across industrial, municipal, and agricultural projects.

Parameter (Specification)

|

Dimension |

PE-100 |

|||||

|

SDR 11 |

SDR 13.6 |

SDR 17 |

SDR 21 |

SDR 26 |

||

|

S 5 |

S 6.3 |

S 8 |

S 10 |

S 12.5 |

||

|

OD |

ND |

PN 16 |

PN 12.5 |

PN 10 |

PN 8 |

PN 6 |

|

(mm) |

(inch) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

|

20 |

1/2" |

2.30 |

- |

- |

- |

- |

|

25 |

3/4" |

2.30 |

- |

- |

- |

- |

|

32 |

1" |

3.00 |

- |

- |

- |

- |

|

40 |

1 1/4" |

3.70 |

- |

2.40 |

- |

- |

|

50 |

1 1/2" |

4.60 |

3.50 |

3.00 |

- |

- |

|

63 |

2" |

5.80 |

4.70 |

3.50 |

- |

- |

|

75 |

2 1/2" |

6.80 |

5.60 |

4.50 |

3.60 |

- |

|

90 |

3" |

8.20 |

6.70 |

5.40 |

4.30 |

3.50 |

|

110 |

4" |

10.00 |

8.10 |

6.60 |

5.30 |

4.20 |

|

125 |

5" |

11.40 |

9.20 |

7.40 |

6.00 |

4.80 |

|

140 |

12.40 |

10.30 |

8.30 |

6.70 |

5.40 |

|

|

160 |

6" |

14.60 |

11.80 |

9.50 |

7.70 |

6.20 |

|

180 |

16.40 |

13.30 |

10.70 |

8.60 |

6.90 |

|

|

200 |

8" |

18.20 |

14.70 |

11.90 |

9.60 |

7.70 |

|

225 |

20.50 |

16.60 |

13.40 |

10.80 |

8.60 |

|

|

250 |

10" |

22.70 |

18.40 |

14.80 |

11.90 |

9.60 |

|

280 |

25.40 |

20.60 |

16.60 |

13.40 |

10.70 |

|

|

315 |

12" |

28.60 |

23.20 |

18.70 |

15.00 |

12.10 |

|

355 |

14" |

32.20 |

26.10 |

21.10 |

16.90 |

13.60 |

|

400 |

16" |

36.30 |

29.40 |

23.70 |

19.10 |

15.30 |

|

450 |

18" |

40.90 |

33.10 |

26.70 |

21.50 |

17.20 |

|

500 |

20" |

45.40 |

36.80 |

29.60 |

23.90 |

19.10 |

|

560 |

22" |

50.80 |

41.20 |

33.20 |

26.70 |

21.40 |

|

630 |

24" |

57.20 |

46.30 |

37.30 |

30.00 |

24.10 |

|

710 |

28" |

64.50 |

52.20 |

42.10 |

33.90 |

27.20 |

|

800 |

32" |

72.60 |

58.80 |

47.40 |

38.10 |

30.60 |

|

900 |

36" |

81.70 |

66.20 |

53.30 |

42.90 |

34.40 |

S: Series classification for wall thickness.

Custom sizes also available.

Hot-selling sizes:

2.5 inch hdpe pipe,12 inch hdpe pipe,14 inch hdpe pipe,15 inch hdpe pipe,16 inch hdpe pipe

18 inch hdpe pipe,20 inch hdpe pipe,24 inch hdpe pipe,30 inch hdpe pipe,60 inch hdpe pipe

|

Diameter |

Meter/ Roll |

Meter/Stick |

||||||||||||

|

OD |

ND |

300m |

200m |

100m |

50m |

12m |

6m |

|||||||

|

(mm) |

(inch) |

|||||||||||||

|

20 |

1/2" |

● |

● |

● |

● |

|

|

|||||||

|

25 |

3/4" |

● |

● |

● |

● |

|

|

|||||||

|

32 |

1" |

● |

● |

● |

● |

|

|

|||||||

|

40 |

1-1/4" |

|

● |

● |

● |

|

|

|||||||

|

50 |

1-1/2" |

|

● |

● |

● |

● |

● |

|||||||

|

63 |

2" |

|

|

● |

● |

● |

● |

|||||||

|

75 |

2-1/2" |

|

|

● |

● |

● |

● |

|||||||

|

90 |

3" |

|

|

|

● |

● |

● |

|||||||

|

110 |

4" |

|

|

|

|

● |

● |

|||||||

|

125 |

5" |

|

|

|

|

● |

● |

|||||||

|

140 |

|

|

|

|

● |

● |

||||||||

|

160 |

6" |

|

|

|

|

● |

● |

|||||||

|

180 |

|

|

|

|

● |

● |

||||||||

|

200 |

8" |

|

|

|

|

● |

● |

|||||||

|

225 |

|

|

|

|

● |

● |

||||||||

|

250 |

10" |

|

|

|

|

● |

● |

|||||||

|

280 |

|

|

|

|

● |

● |

||||||||

|

315 |

12" |

|

|

|

|

● |

● |

|||||||

|

355 |

14" |

|

|

|

|

● |

● |

|||||||

|

400 |

16" |

|

|

|

|

● |

● |

|||||||

|

450 |

18" |

|

|

|

|

● |

● |

|||||||

|

500 |

20" |

|

|

|

|

● |

● |

|||||||

|

560 |

22" |

|

|

|

|

● |

● |

|||||||

|

630 |

24" |

|

|

|

|

● |

● |

|||||||

|

710 |

28" |

|

|

|

|

● |

● |

|||||||

|

800 |

32" |

|

|

|

|

● |

● |

|||||||

|

900 |

36" |

|

|

|

|

● |

● |

|||||||

Feature And Application

Feature:

1.Reliable Connections:

HDPE Pipe use heat fusion jointing system with low notch sensitivity; joint strength exceeds pipe body strength.

2.Excellent Low-Temperature Impact Resistance:

Brittle point below 0°C; maximum operating temperature 40°C; design pressure 8MPa for various climates.

3.Long Service Life (>50 years):

High crack resistance, superior shear strength and elongation at break.

4.Chemical Corrosion Resistance: Withstands acids, alkalis and chemicals; rust-proof; inhibits bacterial/fungal growth.

5.UV & Weather Resistance:

Black PE pipes provide UV protection for outdoor storage/use.

6.Abrasion Resistance:

4 times more wear-resistant than steel pipes with better cost-efficiency.

7.Flexibility:

Adapts to hilly terrain; can bend around obstacles, reducing fittings and installation costs.

8.Low Flow Resistance:

Smooth interior (roughness coefficient: 0.009); 1/200 friction loss vs steel pipes; minimizes pressure loss and scaling.

9.Easy Handling:

Lightweight and flexible, significantly reducing labor/equipment costs vs concrete/galvanized/steel pipes.

10.Installation Convenience:

Available in straight/coiled forms; supports trench/trenchless methods (pipe jacking, directional drilling, sliplining, pipe bursting).

Applications:

1.Water Supply:

HDPE Pipe is ideal for urban systems with safety, hygiene and cost benefits.

2.Sewerage and drainage

Corrosion-resistant for acid/alkali/salt solutions with low maintenance,suc as food & chemical Industries.

3.Slurry & Mineral Transport:

4x more abrasion-resistant than steel for mining/fly ash/dredging.

4.Pipeline Rehabilitation:

Trenchless replacement of concrete/CI/steel pipes, ideal for urban renewal.

5.Landscape Irrigation:

Cost-effective watering solution.

6.Electrical and telecommunication cabling

7.Other Uses:

Landfills, geothermal, aquaculture, fire protection.

Details

*Premium material selection

*Smooth and even surface finish

*Single-step molding process

*Low friction coefficient