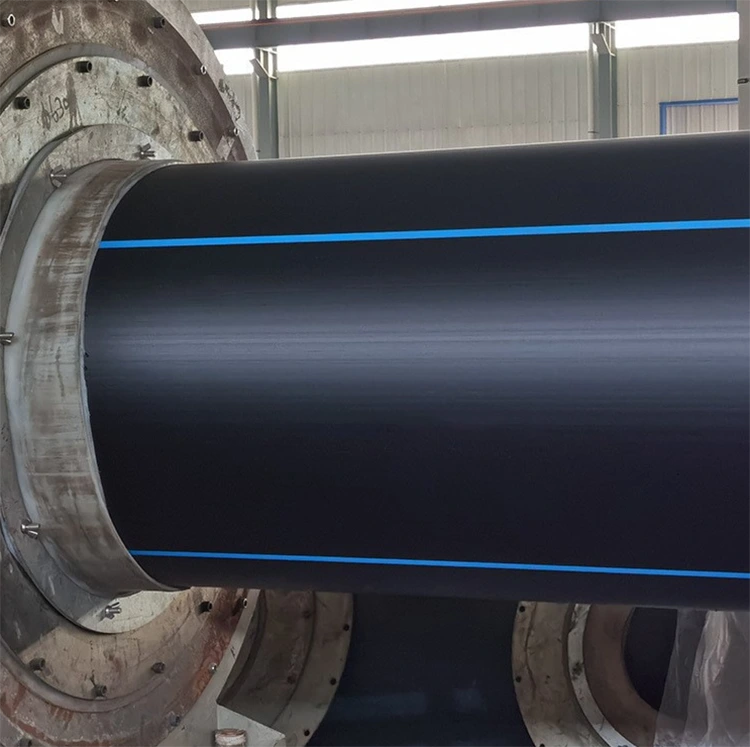

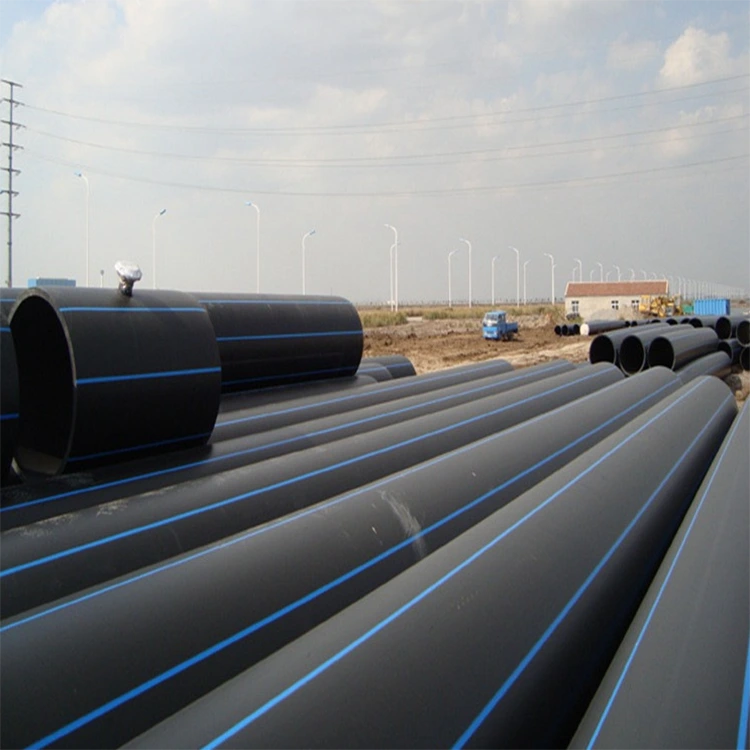

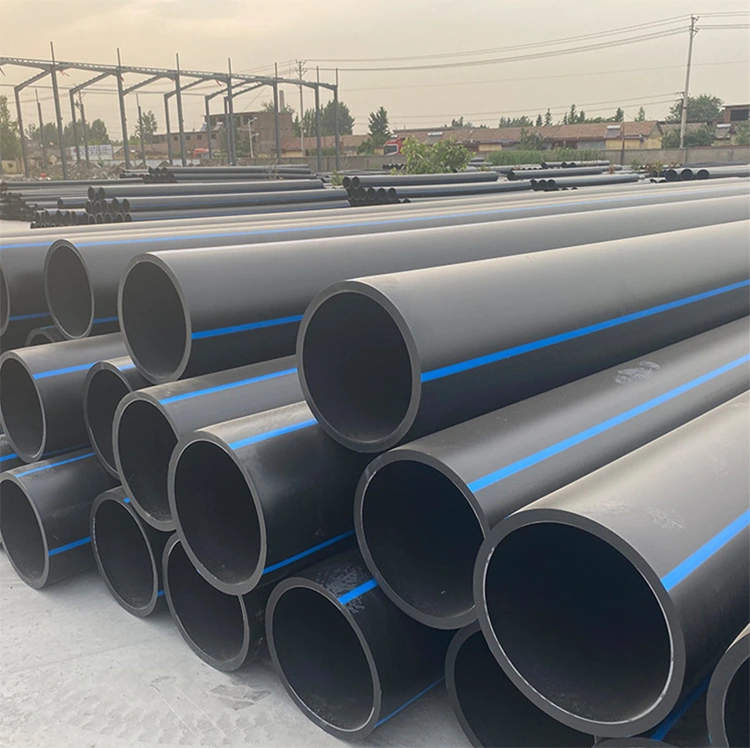

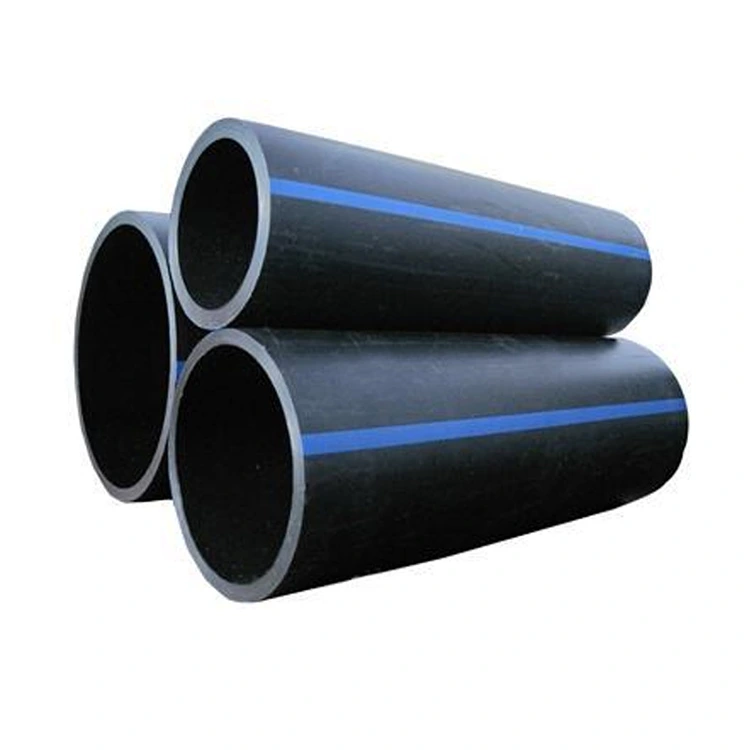

Hot Sale 20mm-225mm Plastic Water Pipe HDPE Farmland Irrigation Pipe

Send Inquiry

HDPE Farmland Irrigation Pipe – 20 mm–225 mm

Company Introduction

Over the years we have worked with large state contractors, including CCCC, CREC and CRCC, supplying materials for a range of transport and infrastructure projects. These collaborations gave Hot Sale 20mm-225mm Plastic Water Pipe HDPE Farmland Irrigation Pipe steady references in the domestic market and the confidence to look outward. In the last few years we began to serve overseas buyers as well, and the response has been positive—farmers value the irrigation lines for their reliability, while engineering clients often mention the balance between price and performance. Our direction is straightforward: keep improving step by step, and remain a company that people are comfortable to work with.

Material Features and Advantages

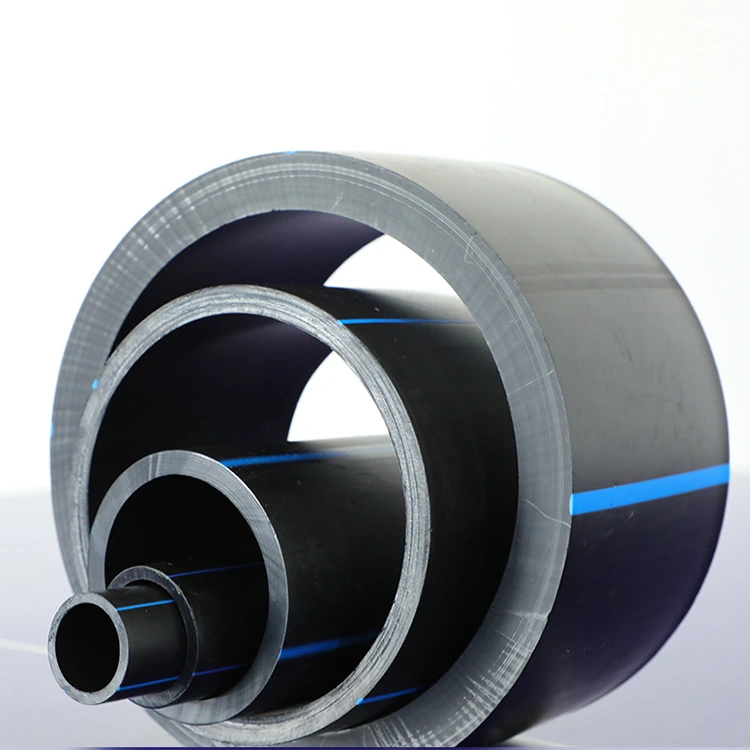

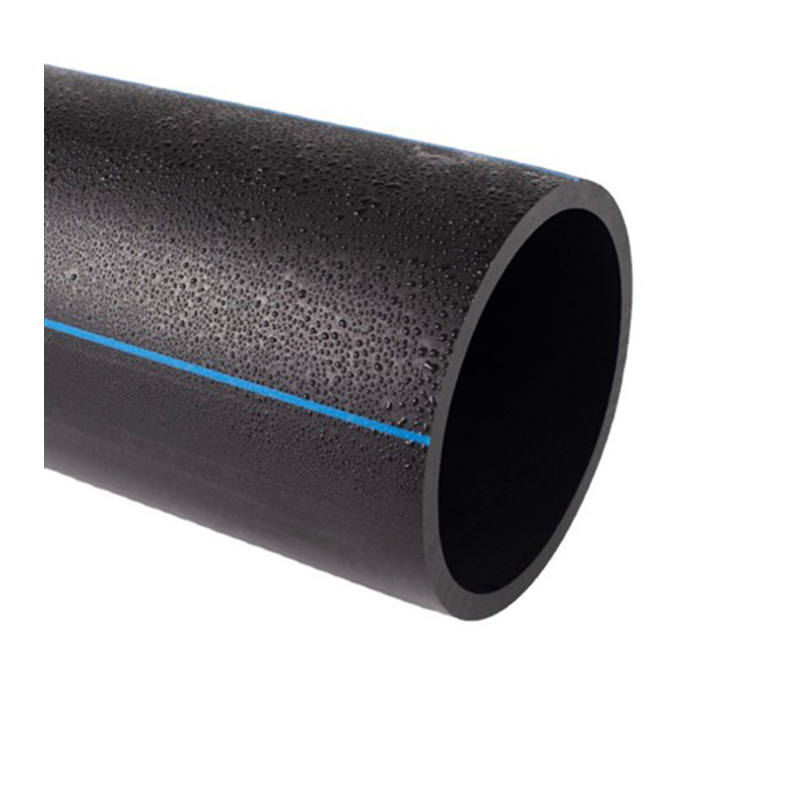

The farmland irrigation pipes are made from HDPE, a tough polyethylene material that holds up well under sun and common agricultural chemicals. Because the inside wall is smooth, water runs with little resistance, which helps keep long irrigation runs from clogging. Farmers who handle the pipes on site often note how light and flexible they feel compared with rigid alternatives, making both transport and installation easier.

The joints are normally connected by heat-fusion, which results in a tight and reliable seal. Since the material is non-toxic, it is safe to use in irrigation and drinking water systems. Costs are also lower than for metal piping, and maintenance is simple, which together make HDPE a practical long-term option for field irrigation and other rural water projects.

Application Scenarios

• Greenhouse irrigation systems

• Open‑field farmland watering

• Drip and sprinkler irrigation projects

• Landscape irrigation

• Water supply for aquaculture or fish farming

• Rural water distribution

Product Features

• Model: listed as “HDPE farmland irrigation pipe”.

• Water absorption is very low—below 0.01% on our listing.

• Processing shrinkage is about 1.0%–2.5%, which we factor in during production and QC.

• Intended use covers industrial water transfer and household/field irrigation; in practice most buyers use it for agriculture and general water projects.

• Platform search tags include “PVC pipe / fittings / valve / butterfly” for cross‑category visibility; the product itself is HDPE.

• Connections can be made by butt‑fusion or with compression fittings—choose based on your on‑site tools and crew experience.

• Recommended working temperature: −40 °C to 40 °C in normal service.

• Shipping is arranged in 20′ or 40′ containers, depending on order volume and size mix.

• Brand mark: East Boom.

• HS code (CN): 39172100.

• Typical tensile strength: around 30–40 MPa as shown on the listing.

• Third‑party marks available by request: SGS / CE / ISO.

• Standard color: black.

• Built for corrosion resistance—works well with fertilized water and common agrochemicals.

• Service life is designed for long‑term use (stated as over 50 years under normal conditions).

• Nominal sizes supplied from DN20 to DN250 (½″–10″).

• Origin: Hebei, China.

• Approximate annual capacity on the listing: 10,000 t/year.

Notes: The details above are taken from our Made‑in‑China product page. For project‑specific requirements (pressure class, coil length, fittings package, or labeling), please tell us your use case and we’ll match the exact spec.

Technical Parameters (Specification Sheet)

|

DN (mm) |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

|

16 |

|

|

|

|

2 |

|

20 |

|

|

2 |

2.3 |

|

|

25 |

|

|

2.3 |

3 |

|

|

32 |

|

|

2.4 |

3 |

|

|

40 |

|

2.3 |

3 |

3.7 |

|

|

50 |

|

2.3 |

2.9 |

3.7 |

4.6 |

|

63 |

2.3 |

2.5 |

3.7 |

4.7 |

5.8 |

|

75 |

2.9 |

3.6 |

4.5 |

5.6 |

6.8 |

|

90 |

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

|

110 |

4.2 |

5.3 |

6.6 |

8.1 |

10 |

|

125 |

4.8 |

6 |

7.4 |

9.2 |

11.4 |

|

140 |

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

|

160 |

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

|

180 |

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

|

200 |

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

|

225 |

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

|

250 |

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |