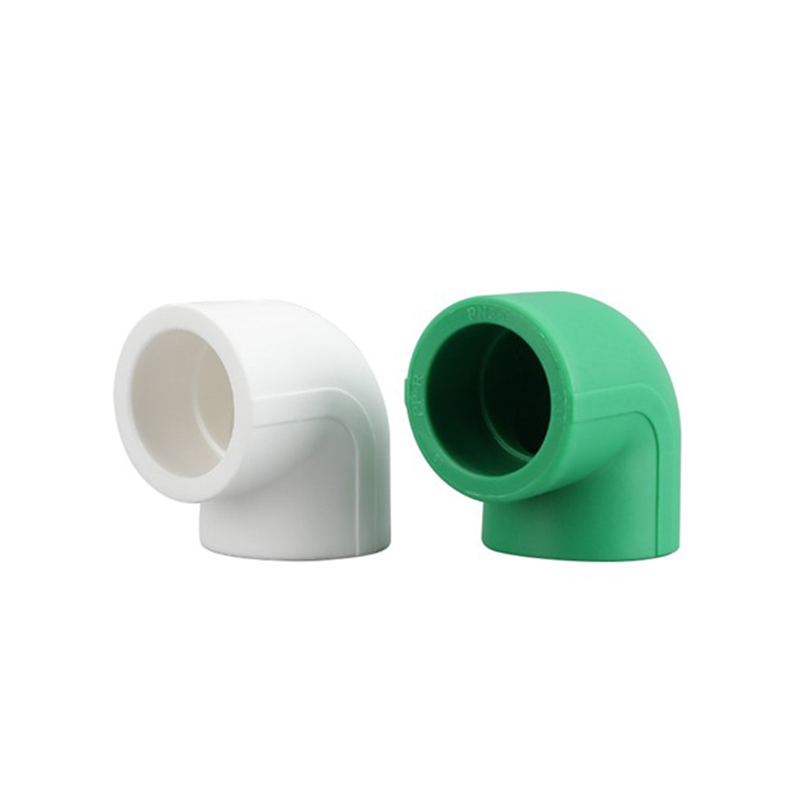

PPR End Cap

Send Inquiry

Introduction

The PPR end cap is a fitting used to seal the end of a pipeline. It is made from high-quality polypropylene (PPR) material and typically has a cap-like shape that fully covers the pipe opening. It is commonly used to close off the end of a pipeline, preventing debris, dust, or moisture from entering and protecting the interior of the pipe from clogging. This fitting is often found in pipelines that are completed or not in use for a long time.

PPR end caps are usually installed using a hot-melt connection method, fusing with the outer wall of the pipe to form a permanent seal. Once installed, the end cap is generally not easy to remove, making it suitable for long-term use.

Parameter (Specification)

|

Spec(mm) |

20 |

25 |

32 |

40 |

50 |

|

63 |

75 |

90 |

110 |

160 |

Feature And Application

Feature:

The hot-melt connection ensures a tight fit between the end cap and the pipe, preventing leakage and maintaining sealing performance over long-term use.

Our PPR end caps are made of PPR material, which is resistant to acids and alkalis and free from corrosion, effectively blocking external impurities and keeping the pipe interior clean.

High temperature and pressure resistance, our PPR end caps are suitable for both hot and cold water piping systems.

Simple hot-melt connection process requires no additional sealing glue or fasteners, ensuring efficient installation.

Excellent aging resistance and long service life, requiring no frequent replacement.

Application:

Our PPR end caps are used to seal the ends of pipelines that are not in use for long periods in building water supply and drainage systems, such as reserved outlets for renovation or fire-fighting pipelines.

Used in agricultural irrigation projects to protect the openings of irrigation pipelines, preventing sediment from entering and causing blockages.

Used to seal the ends of pipelines in industrial fluid transport systems, preventing contamination of the medium.

Temporarily seals extra pipe openings during pipeline maintenance and modification to ensure system integrity.