Oriented Polyvinyl Chloride Pipe

Send Inquiry

Introduction

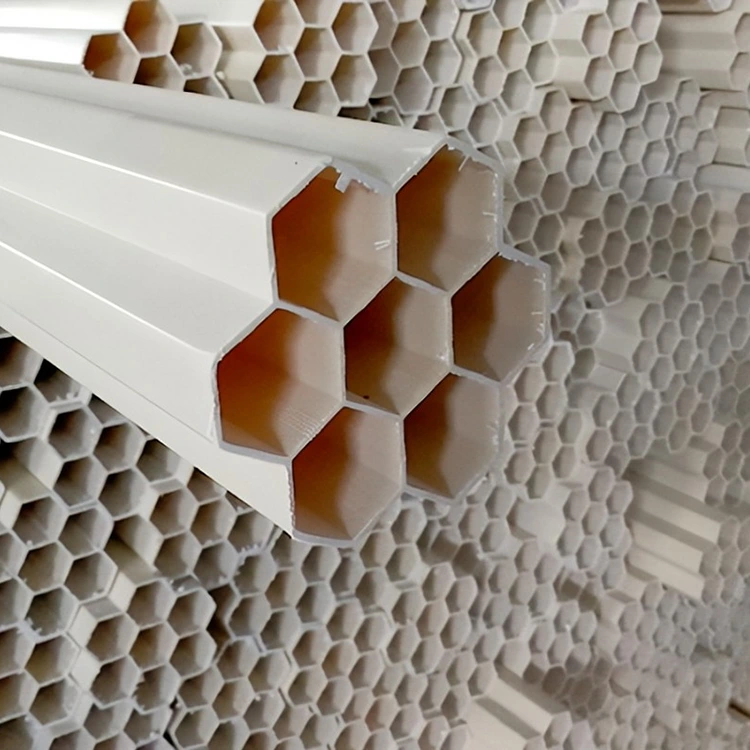

Oriented Polyvinyl Chloride Pipe is an advanced hard plastic pipe, featuring high strength, excellent impact resistance and outstanding chemical resistance Learning nature. Our PVC-O pipes are manufactured through the biaxial orientation process, and their tensile strength is 2 to 3 times that of the standard PVC-U. Applicable to High-pressure water supply, industrial fluid transportation. Because it is light in weight, it saves manpower and is easy to install. Because its inner wall is smooth and has a low friction coefficient, it can effectively reduce head loss and improve the drainage efficiency of the pipeline system. At present, In modern infrastructure and public utility projects,PVC-O pipes have become a better alternative to traditional metal pipes and PVC pipes.

Parameter (Specification)

|

Dimension |

PVC-O Pipe |

||||||||

|

DE |

ID |

Length |

|||||||

|

DN |

PN6.3 |

PN8 |

PN10 |

PN12.5 |

PN16 |

PN20 |

PN25 |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

m |

|

90 |

90 |

85.8 |

85.6 |

84.4 |

83.3 |

84 |

84 |

82.2 |

6 |

|

110 |

110 |

105.4 |

105.2 |

105 |

103.8 |

104 |

103.2 |

101.4 |

|

|

140 |

140 |

- |

- |

- |

133 |

132.4 |

131.2 |

129.2 |

|

|

160 |

160 |

153.2 |

153 |

152.8 |

151.2 |

149 |

150 |

147.6 |

|

|

200 |

200 |

191.4 |

191.2 |

191 |

189 |

186.2 |

187.4 |

184.4 |

|

|

225 |

225 |

- |

- |

- |

213.6 |

212.8 |

210.8 |

207.4 |

|

|

250 |

250 |

239.2 |

239 |

238.8 |

236.2 |

232.8 |

234.2 |

230.6 |

|

|

315 |

315 |

301.4 |

301.2 |

301 |

297.6 |

293.4 |

295.2 |

290.6 |

|

|

355 |

355 |

339.6 |

339.4 |

339.2 |

- |

- |

- |

- |

|

|

400 |

400 |

382.6 |

382.4 |

382.2 |

379.8 |

378.4 |

374.8 |

369 |

|

|

500 |

500 |

- |

- |

- |

474.6 |

472.8 |

468,6 |

461.2 |

|

|

630 |

630 |

- |

- |

- |

597.8 |

595.8 |

590.4 |

581 |

|

Feature And Application

Feature:

1. Superior Physical & Mechanical Properties

Ultra-High Strength: Biaxial orientation process achieves tensile strength of 50-100 MPa (2-3 times higher than standard PVC-U).

Outstanding Compressive Strength: Elastic modulus reaches 4000 MPa; ring stiffness is 1.4× of PVC, 5× of PE, and 4× of MPP.

Excellent Impact Resistance: Our PVC-O pipe’s design stress up to 28 MPa (double that of standard uPVC), with significantly higher pressure-bearing capacity at the same wall thickness. Performs well at -20°C.

High Fatigue Resistance: Withstands ≥2 million pressure cycles.

2. Lightweight & Installation Advantages

Lightweight: Only 1/2 the weight of standard UPVC, 1/2 of HDPE, and 1/7 of cast iron pipes.

High Flexibility: More flexible than standard UPVC, reducing the need for elbows.

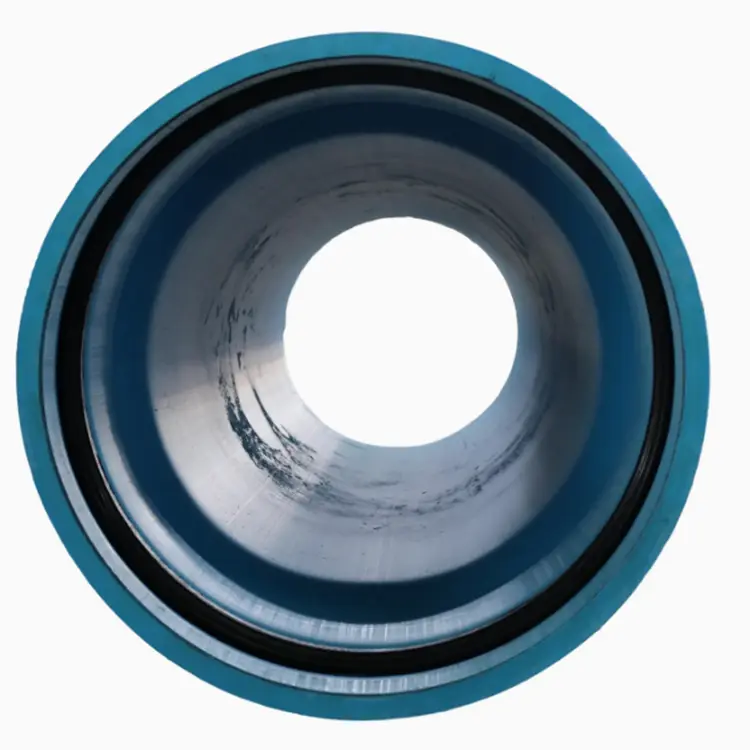

Easy Connection: Rubber ring joint system for simple installation.

3. Exceptional Weather Resistance

Chemical Corrosion Resistance: Our PVC-O pipe resists acids, alkalis, and salts; no quality degradation after 5 hours in 50°C hydrochloric/sulfuric/nitric acid or sodium hydroxide.

UV Resistance: Unique anti-UV material formulation.

Low Maintenance: Rust-free with long service life.

4. High Water Delivery Efficiency

Smooth Interior: 30% lower head loss compared to metal pipes.

5. Safety & Environmental Benefits

Electrical Insulation: Flame-retardant and non-conductive, reducing fire risks.

Eco-Friendly: Our PVC-O pipes are free of cadmium/mercury, 100% recyclable.

Energy Saving: Lower material consumption and carbon emissions vs. PVC/PE/MPP.

6. Technical Assurance

Manufactured using unplasticized PVC (UPVC) modified blend, processed via biaxial stretching (circumferential + axial) for enhanced pressure and impact resistance. Offers comprehensive performance improvements over traditional PVC pipes.

Applications

1.High-pressure water supply

2.Drainage & sewage systems

3.Agricultural irrigation

4.Industrial fluid transport

5.Recycled water systems

6.Seawater desalination

7.Electrical and Telecom protect

Details

Our PVC-O pipes deliver exceptional compressive and impact resistance, exhibiting no brittle fracture under external impact. Even when fully flattened (100% deformation), the pipes can substantially regain their original shape upon load removal.