Clear PVC Pipe: Unmatched Clarity and Performance for Diverse Applications

Discover the superior quality and versatility of our PVC Pipe Fittings. Engineered for precision, our clear PVC pipe offers an exceptional combination of strength and transparency, making it an ideal choice for a wide range of industrial and commercial projects. As a leading component in modern Plastic Pipe systems, it provides the visual monitoring capabilities that opaque pipes cannot. This transparent solution is particularly beneficial in applications where observing fluid flow, checking for blockages, or monitoring process conditions is critical. When integrated with our durable PVC Conduit systems, it ensures reliable protection for electrical wiring while maintaining a clear line of sight. The installation process is streamlined and secure with our comprehensive range of PVC Pipe Connectors, designed to create leak-proof, robust joints that withstand pressure and environmental stress.

The exceptional material properties of <产品名字> set it apart in the market. Manufactured from high-grade, non-toxic PVC compounds, this pipe guarantees long-term durability and resistance to a wide spectrum of chemicals, including many acids, alkalis, and salts. Its inherent UV stabilization prevents yellowing and embrittlement when exposed to sunlight, ensuring the clarity and structural integrity are maintained over time. The smooth interior wall minimizes friction loss, promoting efficient flow rates for both liquids and gases. <产品名字> is also inherently flame-retardant and self-extinguishing, contributing to enhanced safety in various settings. It operates effectively across a broad temperature range, from below-freezing conditions to elevated temperatures, without compromising its performance or transparency. This makes it a reliable choice for demanding environments in chemical processing, water treatment, aquaculture, and food and beverage industries.

Key Specifications of Our Clear PVC Pipe

- Material: High-Grade, UV-Stabilized PVC

- Standard Sizes (Diameter): 1/2", 3/4", 1", 1.5", 2", 3", 4"

- Pressure Rating: Up to 150 PSI (Schedule 40)

- Temperature Range: -10°F to 140°F (-23°C to 60°C)

- Standards Compliance: NSF/ANSI 61 Certified for Potable Water

- Flame Spread Rating: Meets ASTM E84 - Class 1 (Fire Retardant)

Detailed Product Dimensions and Data

| Nominal Size (Inches) | Outside Diameter (OD) (Inches) | Inside Diameter (ID) (Inches) | Wall Thickness (Inches) | Approx. Weight per 10ft (lbs) |

|---|---|---|---|---|

| 1/2" | 0.840 | 0.622 | 0.109 | 0.42 |

| 3/4" | 1.050 | 0.824 | 0.113 | 0.62 |

| 1" | 1.315 | 1.049 | 0.133 | 1.03 |

| 1.5" | 1.900 | 1.610 | 0.145 | 1.75 |

| 2" | 2.375 | 2.067 | 0.154 | 2.55 |

| 3" | 3.500 | 3.068 | 0.216 | 5.25 |

| 4" | 4.500 | 4.026 | 0.237 | 7.50 |

Performance Characteristics

| Property | Test Method | Value / Rating |

|---|---|---|

| Tensile Strength | ASTM D638 | > 7,000 psi |

| Impact Strength (Izod) | ASTM D256 | > 1.0 ft-lb/in |

| Chemical Resistance | - | Excellent to Acids, Alkalis, Salts |

| Light Transmission | - | > 90% |

| Hydrostatic Design Basis (HDB) | ASTM D2837 | 4,000 psi |

Hot Products

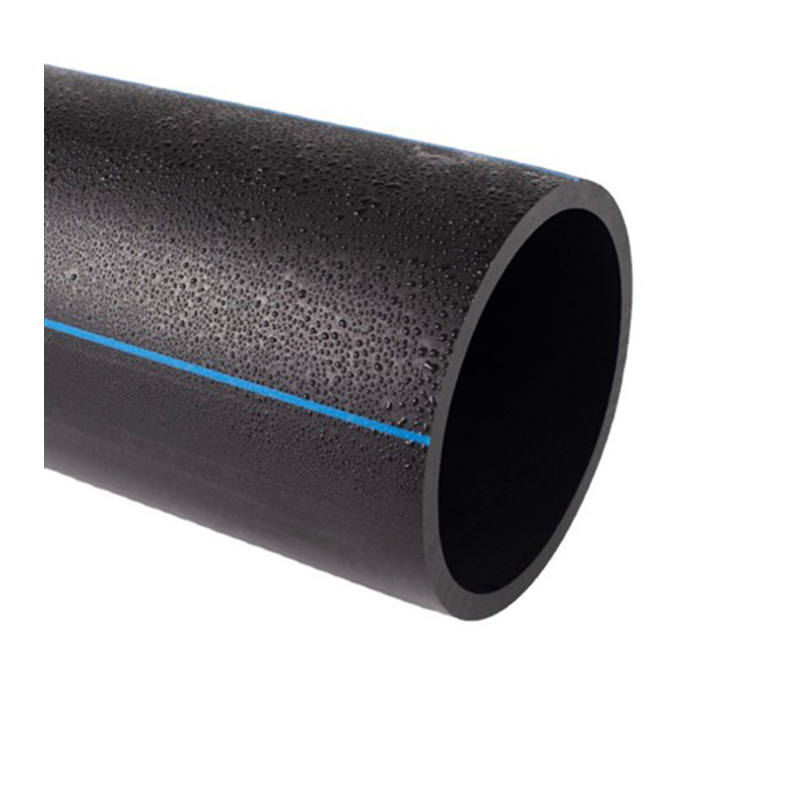

HDPE water pipes for agricultural irrigation

East Boom®, a trusted manufacturer of HDPE water pipes for agricultural irrigation, delivers water efficiently for farm systems. Made in our ISO-certified factory, these durable agricultural HDPE pipes save you money - proven to last for seasons while cutting water loss by up to 30%.High-strength HDPE spirally wound reinforced carat pipe

The High-strength HDPE spirally wound reinforced carat pipe are produced by Eastboom®, a manufacturer specializing in the production of plastic pipeline systems. We possess excellent strength, long service life and stable performance, and are highly suitable for challenging applications such as chemical transportation, water supply networks and industrial drainage.MPP circular single wall corrugated pipe

Eastbooom® is a professional Chinese supplier of MPP circular single wall corrugated pipe, specializing in the production of high-quality pipes across a wide range of applications, providing effective solutions for cable protection in various environments.Industrial MPP Single Wall Corrugated Pipe

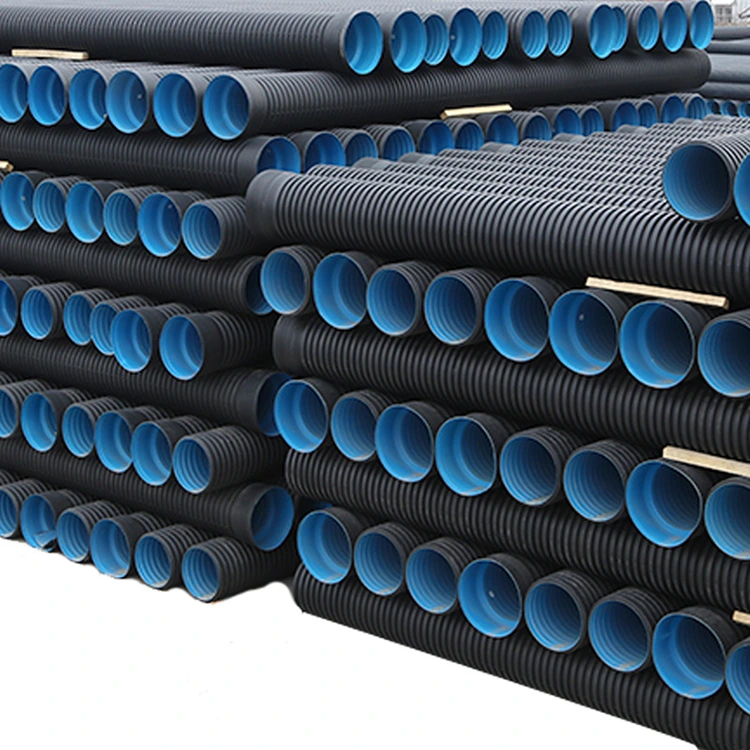

Eastboom® is China MPP Rectangular Single Wall Corrugated Pipe manufacturer and supplier, high quality MPP Rectangular Single Wall Corrugated Pipe specializes in providing lightweight, flame retardant and space saving solutions for customers with cable protection needs.HDPE Double-Wall Corrugated Pipes for Agriculture and Industr

East Boom® is a leading HDPE Double-Wall Corrugated Pipes for Agriculture and Industr factory in China, with extensive experience in the dwc pipe industry. Specializing in reliable and low price double walled drainage pipe solutions.PVC Flanges

Eastboom®'s PVC flanges allow for two pipes to be connected with a tight seal. They are often used to connect accessories to the system, and certain designs will stop the flow in the system as needed. With a wide range of options, quality flange will accommodate many needs when creating a piping system.