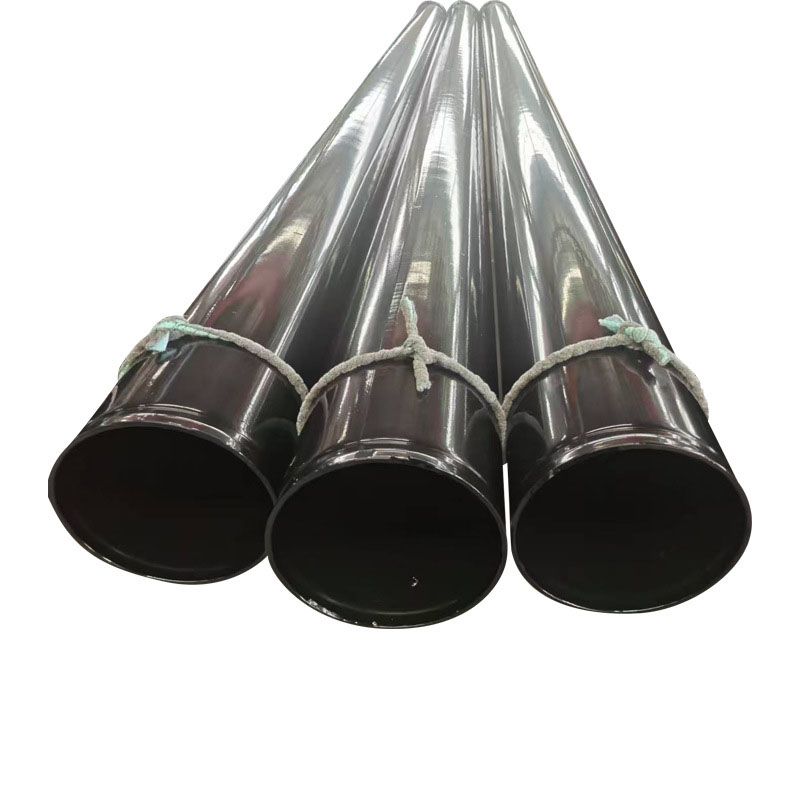

N HAP hot dip plastic steel pipe

Send Inquiry

N HAP hot dip plastic steel pipe is a new generation of anti-corrosion materials, produced via fluidized bed dipping technology. They stand out with high mechanical strength, strong pressure resistance, and excellent electrical insulation, along with high hardness, smooth inner and outer surfaces, and a low friction coefficient. Its advantages go far beyond this: top flame retardant safety features, excellent moisture-proof performance with almost no water absorption (water absorption rate <0.003%), and a wide operating temperature range spanning -40°C to 120°C, enough to conquer various harsh environments.

Key Features & Applications

What Makes It Stand Out

Weather & Low-Temp Resistant

Made for long-term buried use, our N HAP hot dip plastic steel pipe work reliably from -40℃ to 100℃. They hold up perfectly under tough conditions like frost, extreme heat, and humidity—no problem.

Smooth Inner Wall

The inside is super smooth with no burrs, so cables slide right through during installation. This avoids scratches or damage to the insulation, saves time on setup, and cuts down on future maintenance.

Corrosion & Aging Resistance

-Inner/outer resin coating ensures chemical stability, resists corrosion, rust, and aging

High Mechanical Strength

-Comparable to steel pipes in impact, bending, and pressure resistance; long service life, -outperforms standard plastic mining pipes

Strong Coating Adhesion

-Adhesion strength ≥35 N/cm, low water absorption (<0.0003%), excellent water immersion resistance

Self-Lubricating

-Our N HAP Hot dip Coated Steel Pipes have smooth inner wall prevents scaling, reduces flow resistance, increases throughput by 30%

Flexible Connection Methods

-Socket/spigot joints, clamp connections, compatible with flanges and quick couplers

Corrosion & Scaling Resistance

- This [equipment/system/solution] is suitable for high-sulfur water and hard water containing calcium/magnesium ions. It does not require frequent component replacement, has low consumables, and has low maintenance costs.

Eco-Friendly & Safe

-PE polyethylene powder coating, non-toxic, odorless, and clean

Lightweight

-Easier to transport and install compared to traditional steel pipes

Applications:

1.Our product are used in underground protection for power/communication cables

2.Bridge/river/road-crossing conduit for cables

3.Mine cable protection pipes

4.Reclaimed water/seawater transport

5.Drainage and sewage systems

6.Corrosive fluid transport in petroleum/chemical industries

Details

N HAP hot dip plastic steel pipe feature push-on joints for quick and easy installation.

Parameter (Specification)

|

Pipe Specifications |

||||||||||||||||||||

| Dimension |

PE Plastic-coated Steel Pipes |

|||||||||||||||||||

| DN |

Wall Thickness (mm) |

|||||||||||||||||||

| (mm) | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | 1.6 | 1.7 | 1.8 | 1.9 | 2 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 |

| 114 |

- |

- |

- |

- |

- |

- |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

- |

- |

- |

| 175 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

● |

● |

● |

● |

● |

● |

● |

● |

| 200 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

- |