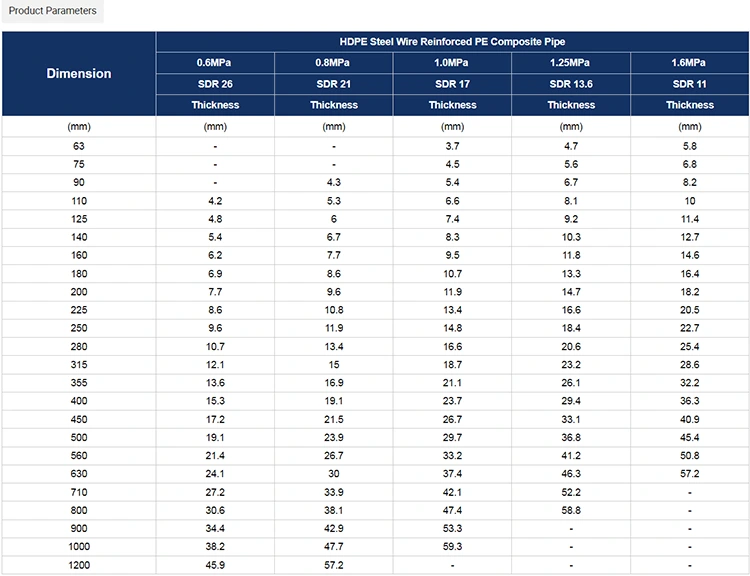

Steel Wire Reinforced PE Composite Pipe for Water

Send Inquiry

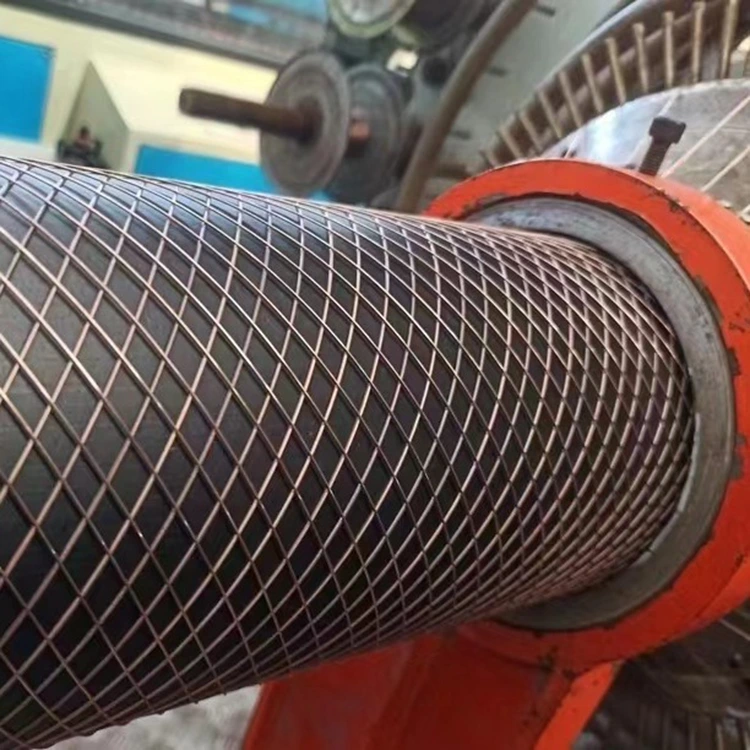

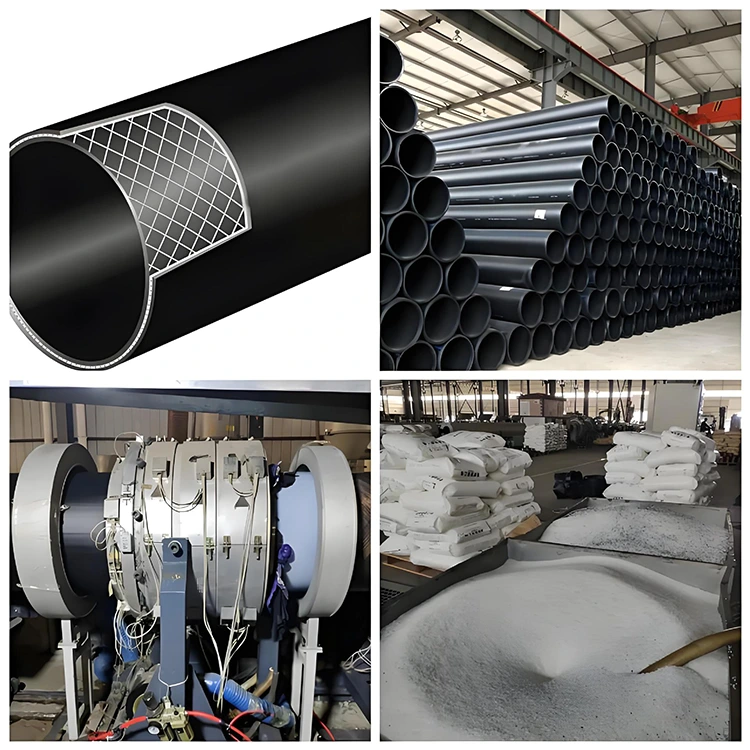

This Steel Wire Reinforced PE Composite Pipe for Water is characterized by a high-strength steel wire mesh skeleton integrated with thermoplastic polyethylene (referred to as HDPE for short). The crisscross galvanized steel wire reinforcement layer is fully enclosed within an HDPE matrix with the help of modified adhesive resin. This process forms an excellent bond, which integrates the advantages of both materials and at the same time gets rid of their respective shortcomings.

Features:

1.High strength: the steel mesh skeleton significantly improves the compression and impact resistance.

2.Corrosion resistance: The plastic layer of the pipeline can effectively stand against chemical corrosion. This characteristic helps keep the pipeline’s structural stability when applied in environments with chemical activity.

3.Long service life: With strong aging resistance, the pipeline can sustain stable operational performance for over 50 years, thereby guaranteeing a prolonged service life.

4.Easy installation: This pipe is lightweight in design, which simplifies carrying and moving processes during construction and thus facilitates installation work.

5.One-piece structure: The skeleton (of the pipe) and HDPE layer are combined into a single, indivisible unit. This integrated structure can effectively prevent the occurrence of delamination between different layers.

Application Fields:

1. Long-Distance High-Pressure Water Supply Projects

2. Our HDPE steel wire reinforced pipes used in buried rainwater, drainage and sewage systems.

3. Transportand Discharge Systems for Corrosive Chemical Solvents

4. Slurry Transportand Wastewater Discharge in Mining Operations

5. Agricultural Irrigation Pipelines

6. Oil and Gas Transportation

7. Firefighting High-Pressure Water Supply Pipe