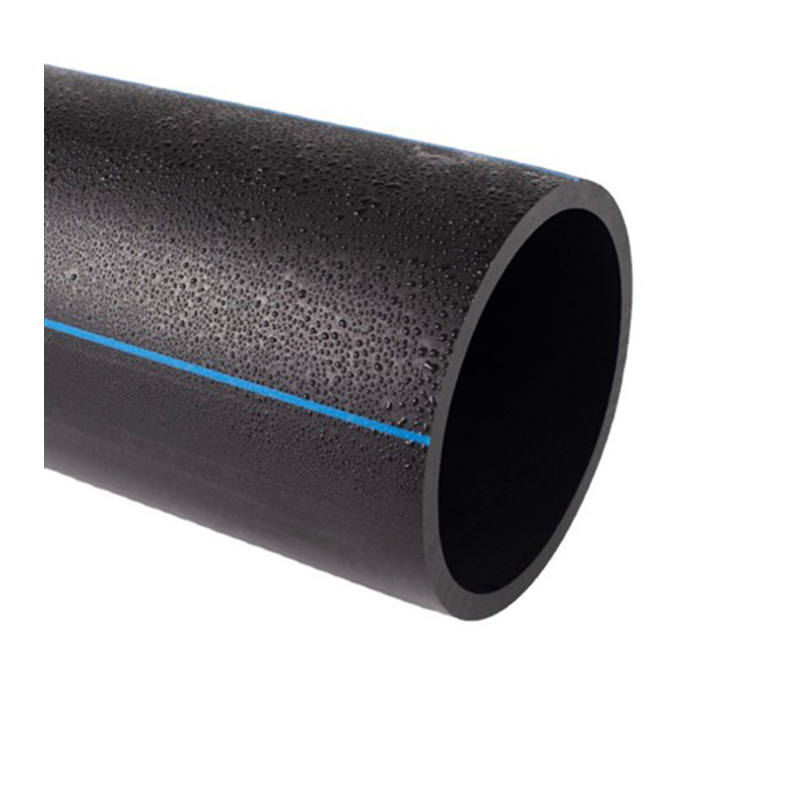

China HDPE Tubing Manufacturer, Supplier, Factory

For demanding fluid and gas conveyance applications, High Density Polyethylene Pipe stands out as a premier choice due to its exceptional durability and chemical resistance. This robust Polyethylene Pipe is engineered to withstand harsh environmental conditions, including extreme temperatures and abrasive soils, making it ideal for both industrial and municipal uses. The flexibility of this specific Pe Pipe allows for cost-effective installation with fewer fittings, reducing potential leak points. Furthermore, its smooth interior surface ensures minimal friction loss, promoting efficient flow rates. Its non-conductive properties also make it an excellent choice for use as an HDPE Electrical Conduit, providing superior protection for electrical and fiber optic cables against moisture and corrosion.

The intrinsic properties of <产品名字> contribute significantly to its long service life and low maintenance requirements. Its high resistance to stress cracking ensures structural integrity under constant pressure, while its immunity to electrochemical corrosion eliminates a common failure point found in metallic alternatives. This material is also environmentally sound, as it is non-toxic and fully recyclable, aligning with modern sustainability goals. The lightweight nature of the tubing simplifies handling and transportation, leading to reduced installation time and labor costs. Its ability to be joined using heat fusion creates seamless, monolithic systems that are exceptionally leak-proof.

Key Specifications of HDPE Tubing

- Material Grade: PE100, PE4710

- Standard Dimension Ratio (SDR): Ranges from SDR11 to SDR26

- Pressure Rating (PN): PN6 to PN16

- Temperature Range: -50°C to 60°C (-58°F to 140°F)

- Standard Colors: Black (with blue or yellow stripes for identification)

- Jointing Method: Butt Fusion, Electrofusion, Socket Fusion

| Nominal Size (mm) | Outside Diameter (mm) | SDR11 Pressure Rating (Bar) | SDR17 Pressure Rating (Bar) |

|---|---|---|---|

| 20 | 20 | 16 | 10 |

| 25 | 25 | 16 | 10 |

| 32 | 32 | 16 | 10 |

| 40 | 40 | 16 | 10 |

| 50 | 50 | 16 | 10 |

| 63 | 63 | 16 | 10 |

| 75 | 75 | 16 | 10 |

| 90 | 90 | 16 | 10 |

| 110 | 110 | 16 | 10 |

| 125 | 125 | 16 | 10 |

| 140 | 140 | 16 | 10 |

| 160 | 160 | 16 | 10 |

| 180 | 180 | 16 | 10 |

| 200 | 200 | 16 | 10 |

| 225 | 225 | 16 | 10 |

| 250 | 250 | 16 | 10 |

| 280 | 280 | 16 | 10 |

| 315 | 315 | 16 | 10 |

Applications and Certifications

- Water Supply Mains: Potable water distribution systems.

- Gas Distribution: Safe conveyance for natural gas.

- Industrial Process Piping: Handling corrosive chemicals and slurries.

- Mining and Dredging: Slurry and tailings transportation.

- Electrical and Communications Conduit: Protection for power and data cables.

- Standards Compliance: Meets or exceeds ASTM D3035, EN 12201, ISO 4427, and AWWA C901/C906.

Hot Products

HDPE Female Adaptor

Eastboom® is a trusted HDPE Female Adaptor manufacturer and supplier. Our female adapters cater to quick installation, leak-proofing, and compatibility with a variety of systems important in water, irrigation, and plumbing installations that require conversion from plastic to metal.HDPE water pipes for agricultural irrigation

East Boom®, a trusted manufacturer of HDPE water pipes for agricultural irrigation, delivers water efficiently for farm systems. Made in our ISO-certified factory, these durable agricultural HDPE pipes save you money - proven to last for seasons while cutting water loss by up to 30%.PVC Reducing Tee

EastBoom® 's PVC Reducing Tee is designed to precisely connect three pipes of different sizes, made of high-quality PVC material, making them ideal for market drainage and water supply piping systems. Eastboom®, as a leading manufacturer and supplier of PVC tee reducers in China, provides high-quality fittings for pipes in various environments.Oriented Polyvinyl Chloride Pipe

East boom®is a China Oriented Polyvinyl Chloride Pipe factory,manufacturing large diameter PVC-O pipes for municipal, agricultural, and industrial applications. We offer customized PVC-O pipes and flexible MOQ for global distributors.High Strength PVC Double Wall Corrugated Pipe

East Boom® is a leading Chinese manufacturer that specializes in advanced PVC-U double wall corrugated drainage pipes. The High Strength PVC Double Wall Corrugated Pipe manufactured by this company are marked by high ring stiffness and excellent corrosion resistance, which makes them highly suitable for municipal engineering, industrial operations, and agricultural applications.Compression Resistant HDPE Equal Cross

EastBoom® is a trusted manufacturer and supplier of Compression Resistant HDPE Equal Cross in China. Our fittings can achieve stable fluid splitting or merging in pressure piping systems, and their pressure resistance ensures that system integrity is not affected.