China HDPE Butt Fusion Manufacturer, Supplier, Factory

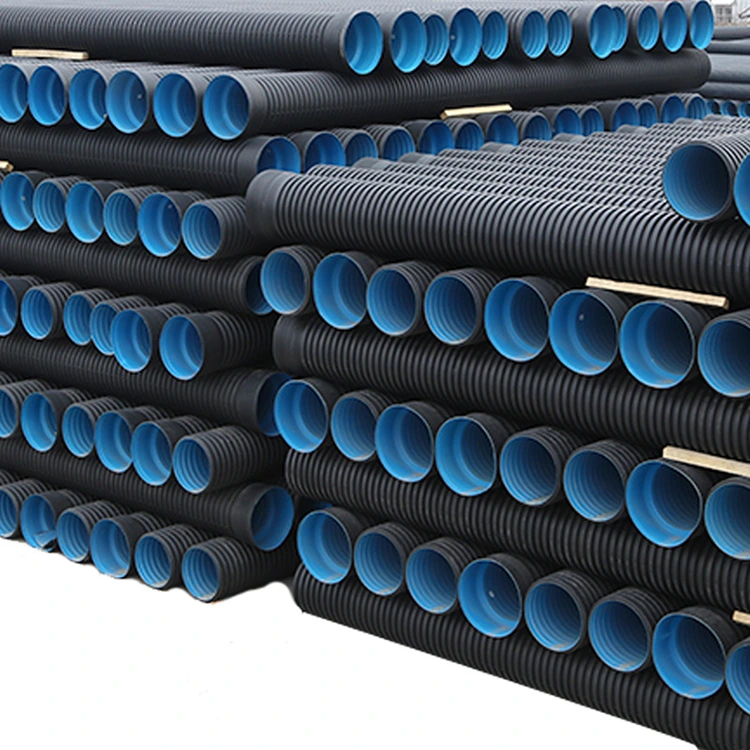

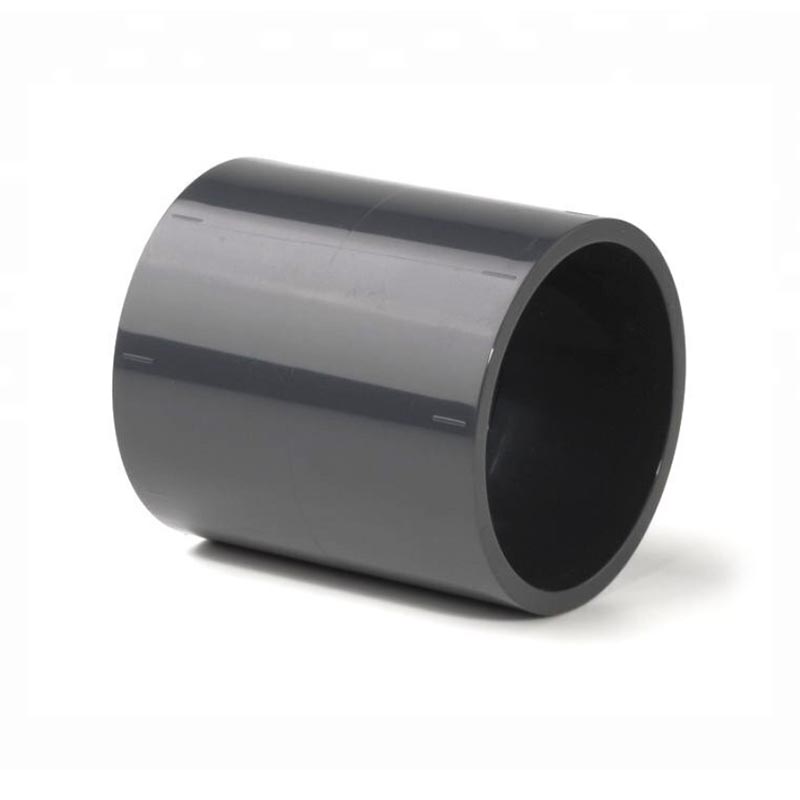

For critical infrastructure projects requiring durable and leak-free fluid transport systems, HDPE Butt Fusion stands as the premier joining methodology. This heat fusion technique creates permanent, monolithic joints that are as strong as the pipe itself, making it the ideal choice for demanding applications such as water mains, gas distribution, and industrial process piping. Its superiority is particularly evident when integrating related components like HDPE Culvert Pipe for drainage systems, HDPE Corrugated Pipe for subsurface protection, and standard pipes such as HDPE Dr11. The process is also essential for installing fittings like an HDPE Coupling to repair or extend pipelines. The resulting system is exceptionally resistant to corrosion, chemical attack, and ground movement, ensuring long-term performance and significantly reducing lifecycle costs.

The HDPE Butt Fusion process involves a precise sequence of operations to ensure joint integrity. First, the pipe ends are meticulously cleaned and prepared. They are then aligned in a specialized fusion machine where a facing tool trims the ends to ensure they are perfectly square and clean. A heating plate, set to a specific temperature, is inserted between the pipe ends. Once the material reaches the correct melt temperature, the plate is removed, and the two molten surfaces are brought together under a controlled pressure. This pressure is maintained as the joint cools, forming a seamless, homogeneous bond. The key to a successful <产品名字> joint lies in strict adherence to established parameters, which vary based on the pipe's dimensions and material grade.

Critical Parameters for HDPE Butt Fusion

- Heating Plate Temperature: Typically between 400°F and 500°F (204°C - 260°C), calibrated for the specific PE material grade.

- Heating Time (Soak Time): The duration the pipe ends are held against the heating plate. This is calculated based on the pipe's wall thickness.

- Fusion Pressure: The pressure applied to join the molten pipe ends, crucial for molecular interdiffusion.

- Cooling Time: The period the joint must remain under pressure to cool and solidify completely before handling.

- Pipe End Preparation: Ensuring ends are clean, square, and free of contaminants is a non-negotiable first step.

| Pipe Diameter (inches) | Heating Time (seconds) | Fusion Pressure (PSI) | Cooling Time (minutes) |

|---|---|---|---|

| 4" | 45 - 60 | 75 - 100 | 8 - 10 |

| 8" | 90 - 120 | 75 - 100 | 15 - 20 |

| 12" | 135 - 180 | 75 - 100 | 25 - 30 |

| 24" | 270 - 360 | 75 - 100 | 45 - 60 |

Proper execution of the HDPE Butt Fusion process demands trained operators and well-maintained equipment. Regular calibration of the heating plate temperature and pressure gauges is essential for consistency. Visual inspection of the bead formation is a primary quality control check; a uniform bead around the entire circumference indicates a good fusion. For critical applications, non-destructive testing methods may be employed to verify joint integrity. By mastering these parameters and procedures, engineers and contractors can leverage the full benefits of HDPE, creating robust pipeline systems designed to last for decades with minimal maintenance.

Hot Products

Unplasticized Polyvinyl Chloride Pipe

East Boom® is a China Unplasticized Polyvinyl Chloride Pipe supplier, offering wholesale pvc u pipe. Our PVC U pipe have stable inventory in stock, our pipes widely used in water supply and drainage systems. we serve customers in Asia and Europe.PPR Short Pipe Clamp For Water Pipes

EASTBOOM® manufactures PPR Short Pipe Clamp For Water Pipes in China, offering modern clamping solutions. We provide high-quality, compact, and durable clips for plumbing, HVAC, and industrial applications. Request a custom quote today.HDPE Steel Wire Reinforced PE Composite Pipes

EAST BOOOM® is a professional HDPE Steel Wire Reinforced PE Composite Pipes supplier in China. EAST BOOOM manufactures advanced composite pipes featuring a steel-HDPE fusion for crack resistance, 30% smoother flow than steel pipe, and customizable pressure ratings for mining, oil/gas, and high-pressure water systems.PVC Eccentric Reducer

EastBoom® manufactures high quality PVC Eccentric Reducers from durable UPVC, offering precise, turbulence-reducing eccentric designs for seamless pipe connections in drainage, chemical, and irrigation systems.PVC Female Adapter

Eastboom®'s quality PVC Female Adapter is a PVC pipe fitting for connecting two male pipes. It is made of polyvinyl chloride (PVC) material that it's two sections are internally threaded, which ensures a safe and leak-free connection of the pipes.Drainage Engineering HDPE 90° Elbow

Eastboom® is a China HDPE 90 Degree Elbow manufacturer and supplier, our advanced HDPE 90 Degree Elbows are ideal for a variety of piping systems for water supply, drainage, gas and irrigation.