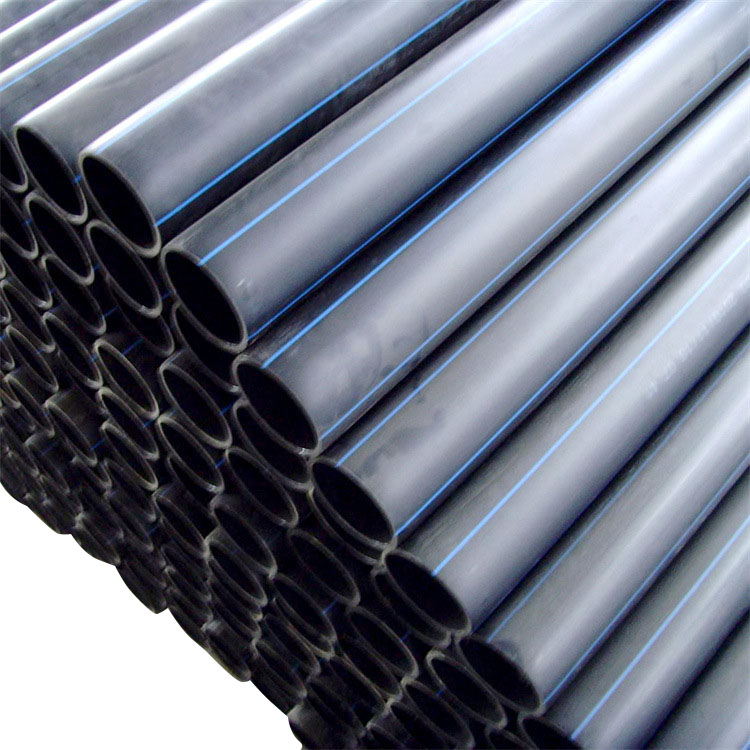

China Corrugated High Density Polyethylene Pipe Manufacturer, Supplier, Factory

Corrugated High Density Polyethylene (HDPE) Pipe represents a significant advancement in modern drainage and fluid management systems. Engineered for superior performance, these pipes offer exceptional durability, chemical resistance, and a long service life, making them an ideal choice for a wide range of applications from agricultural and residential drainage to large-scale civil and environmental projects.

Key Features of Corrugated HDPE Pipe

The inherent properties of HDPE material, combined with a corrugated design, create a pipe solution that outperforms traditional materials like concrete or PVC. Below are the primary features that define its performance.

- Exceptional Durability and Impact Resistance: HDPE's high tensile strength allows the pipe to withstand heavy loads and resist cracking, ensuring structural integrity even under demanding conditions.

- Superior Chemical Resistance: Impervious to a wide range of corrosive soils, chemicals, and acidic environments, making it perfect for industrial and agricultural effluent systems.

- Lightweight and Flexible: The lightweight nature simplifies handling, transportation, and installation, significantly reducing labor and equipment costs. Its flexibility allows it to conform to the grade of the trench, minimizing the need for fittings.

- Long Service Life: Resistant to abrasion, biological growth, and electrochemical corrosion, HDPE pipes are designed to last for decades with minimal maintenance.

- Hydraulic Efficiency: The smooth interior liner (in dual-wall profiles) ensures excellent flow characteristics, reducing the risk of blockages and sediment buildup.

Technical Specifications and Product Parameters

Our corrugated HDPE pipes are manufactured to meet or exceed industry standards, including AASHTO M294 and ASTM F2306. The following tables detail the standard specifications for our most common product lines.

Standard Size and Dimension Ratios (DR)

| Nominal Size (Inches) | Outside Diameter (mm) | Inside Diameter (mm) | Dimension Ratio (DR) | Standard Length (meters) |

|---|---|---|---|---|

| 4" | 114.3 | 99.2 | 17 | 6.1 or 12.2 |

| 6" | 168.3 | 150.8 | 17 | 6.1 or 12.2 |

| 8" | 219.1 | 198.2 | 17 | 6.1 or 12.2 |

| 12" | 313.2 | 287.0 | 21 | 6.1 |

| 18" | 457.2 | 421.6 | 26 | 6.1 |

| 24" | 609.6 | 565.2 | 32.5 | 6.1 |

Material Properties and Performance Data

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D1505 | 0.955 g/cm³ |

| Melt Flow Index (190°C/2.16kg) | ASTM D1238 | 0.8 g/10 min |

| Tensile Strength at Yield | ASTM D638 | 26 MPa (3800 psi) |

| Flexural Modulus | ASTM D790 | 1000 MPa (145,000 psi) |

| Hydrostatic Design Basis (HDB) at 73°F (23°C) | ASTM D2837 | 1600 psi (11.0 MPa) |

| Chemical Resistance | N/A | Excellent resistance to acids, alkalis, and salts |

| Operating Temperature Range | N/A | -70°F to 140°F (-57°C to 60°C) |

Common Applications

- Stormwater Management: Subsurface drainage, detention/retention systems, and storm sewers.

- Agricultural Drainage: Field drainage, irrigation systems, and outlet pipes.

- Land Development: Foundation drainage, French drains, and perimeter drains for residential and commercial properties.

- Highway and Railway Construction: Culverts, underdrains, and edge drains.

- Environmental Projects: Landfill leachate collection, methane gas venting, and contaminated land remediation.

The joining system for corrugated HDPE pipe is typically achieved with snap-on couplers or bell-and-spigot joints with integral gaskets, providing a water-tight seal that is easy to install without specialized tools. For specific project requirements, custom fittings including tees, elbows, and wyes are readily available.

Hot Products

HDPE Male Threaded Tee

Eastboom® is one of the very good HDPE male threaded tee manufacturers and suppliers in China, our fittings are made of PE100 material, which has a very good performance, with corrosion resistance, stable mechanical properties, and easy to adjust and install.PVC Butterfly Valves

EastBoom® Pipes' PVC butterfly valves feature a disc. The valve body can be rotated 90 degrees to control the size of the flow rate or close quickly, but in some large-diameter piping systems, the cost and weight of Pvc butterfly valves are lower than those of ordinary valvesPVC Flanges

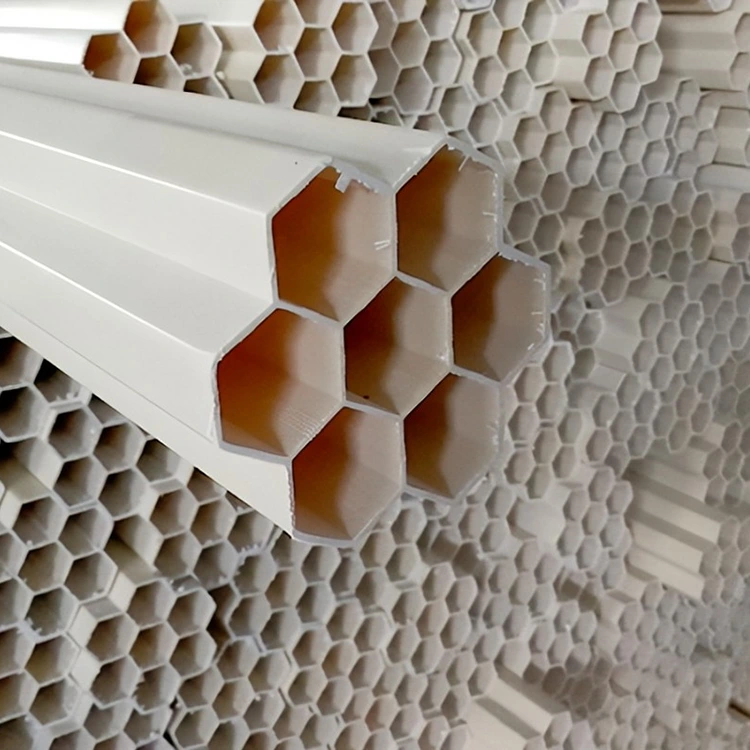

Eastboom®'s PVC flanges allow for two pipes to be connected with a tight seal. They are often used to connect accessories to the system, and certain designs will stop the flow in the system as needed. With a wide range of options, quality flange will accommodate many needs when creating a piping system.White PVC Water Supply Tube Pipe for Irrigation

EastBoom® as a China PVC pipe supplier, offering wholesale White PVC Water Supply Tube Pipe for Irrigation with competitive pricing and reliable quality, widely used in water supply, drainage, and industrial piping systems..Mpp Corrugated Pipe

Eastbooom® is a Mpp Corrugated Pipe factory based in China that places great emphasis on manufacturing high-quality MPP Round Single Wall Corrugated Pipe. This MPP pipe offers an effective solution for protecting cables under various environmental conditions.HDPE Steel Wire Reinforced PE Composite Pipe

As a China HDPE steel wire reinforced pipe supplier, EAST BOOOM manufactures advanced composite pipes featuring: HDPE Steel Wire Reinforced PE Composite Pipe for crack resistance, 30% smoother flow than steel pipes, custom pressure ratings.Ideal for mining, oil/gas, and high-pressure water systems. Request your composite pipe quotation now!