China PVC Pipe Diameters Manufacturer, Supplier, Factory

Navigating the world of PVC piping requires a clear understanding of dimensions to ensure a perfect fit for any project. Our comprehensive selection of Polyvinyl Chloride Pipes is engineered to meet a vast array of industrial, residential, and commercial applications. Whether you are planning a complex irrigation system, a new plumbing installation, or a custom DIY project, selecting the correct pipe diameter is the first critical step. Proper sizing is essential not only for flow efficiency but also for ensuring compatibility with our extensive range of high-quality PVC Fittings. For applications requiring visual monitoring of fluid flow, our Clear PVC Pipe offers the same dimensional precision and durability in a transparent form. A commonly requested size for various pressure and drainage applications is the versatile 1 1 2 PVC Pipe, which provides an excellent balance of capacity and strength.

Our PVC piping system, <产品名字>, is manufactured to the highest industry standards, ensuring exceptional performance and longevity. The product's dimensional consistency is critical for leak-free systems and ease of installation. Below, you will find detailed specifications for our most popular sizes to assist in your selection process.

Standard PVC Pipe Diameters and Specifications

The following list outlines the nominal sizes available in the <产品名字> product line. Nominal size refers to the approximate internal diameter of the pipe and is the standard reference used in the industry.

- 1/2 inch Schedule 40 & 80

- 3/4 inch Schedule 40 & 80

- 1 inch Schedule 40 & 80

- 1 1/4 inch Schedule 40 & 80

- 1 1/2 inch Schedule 40 & 80

- 2 inch Schedule 40 & 80

- 3 inch Schedule 40 & 80

- 4 inch Schedule 40 & 80

- 6 inch Schedule 40 & 80

- 8 inch Schedule 40

Detailed Dimensional Data for <产品名字>

For precise engineering and planning, the exact outer diameter, wall thickness, and inner diameter are paramount. The table below provides these critical measurements for Schedule 40 and Schedule 80 pipes, which denote different pressure ratings.

| Nominal Size (inches) | Schedule | Outer Diameter (inches) | Wall Thickness (inches) | Inner Diameter (inches) |

|---|---|---|---|---|

| 1/2 | 40 | 0.840 | 0.109 | 0.622 |

| 1/2 | 80 | 0.840 | 0.147 | 0.546 |

| 3/4 | 40 | 1.050 | 0.113 | 0.824 |

| 3/4 | 80 | 1.050 | 0.154 | 0.742 |

| 1 | 40 | 1.315 | 0.133 | 1.049 |

| 1 | 80 | 1.315 | 0.179 | 0.957 |

| 1 1/4 | 40 | 1.660 | 0.140 | 1.380 |

| 1 1/4 | 80 | 1.660 | 0.191 | 1.278 |

| 1 1/2 | 40 | 1.900 | 0.145 | 1.610 |

| 1 1/2 | 80 | 1.900 | 0.200 | 1.500 |

| 2 | 40 | 2.375 | 0.154 | 2.067 |

| 2 | 80 | 2.375 | 0.218 | 1.939 |

| 3 | 40 | 3.500 | 0.216 | 3.068 |

| 3 | 80 | 3.500 | 0.300 | 2.900 |

| 4 | 40 | 4.500 | 0.237 | 4.026 |

| 4 | 80 | 4.500 | 0.337 | 3.826 |

| 6 | 40 | 6.625 | 0.280 | 6.065 |

| 6 | 80 | 6.625 | 0.432 | 5.761 |

| 8 | 40 | 8.625 | 0.322 | 7.981 |

Understanding these dimensions is crucial for system design. The outer diameter must be compatible with fittings, while the inner diameter directly impacts flow rates. Schedule 80 pipes have thicker walls than Schedule 40, resulting in a higher pressure rating but a slightly smaller inner diameter. This data ensures you can make an informed decision for your specific hydraulic or pneumatic requirements.

Hot Products

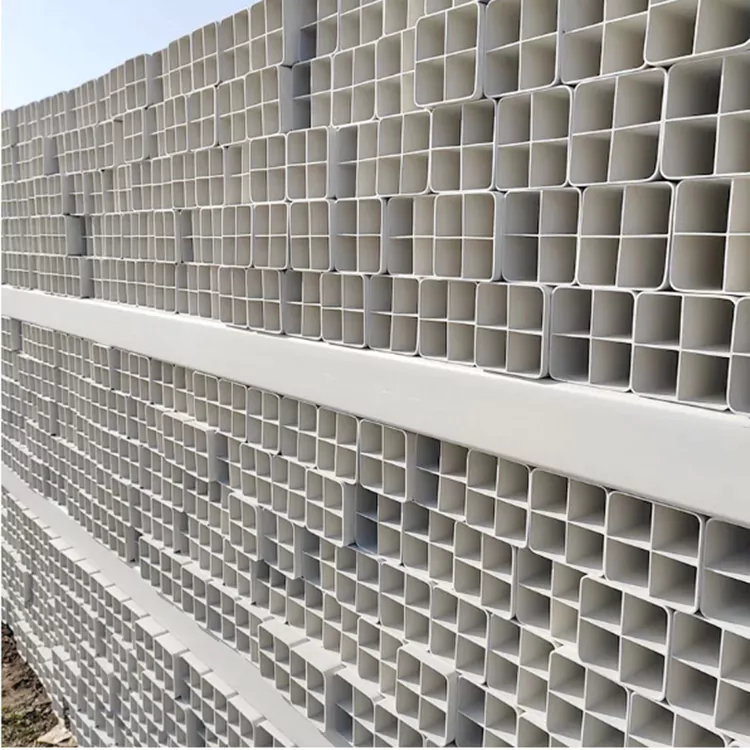

PVC-U Grid Pipes for Underground Cable Protection

East Boom® is a specialized Chinese manufacturer dedicated to the production of PVC-U Grid Pipes for Underground Cable Protection. The enterprise focuses on wholesale distribution of these products, which not only retain steady and dependable quality but also offer substantial cost benefits.In addition to offering cellular core PVC pipes, East Boom® also provides efficient delivery services and accepts customized orders for large-volume purchases. These PVC pipes designed for underground use are widely applied in cable protection and a variety of infrastructure construction projects.HDPE Wire Conduit Power Protection Pipe

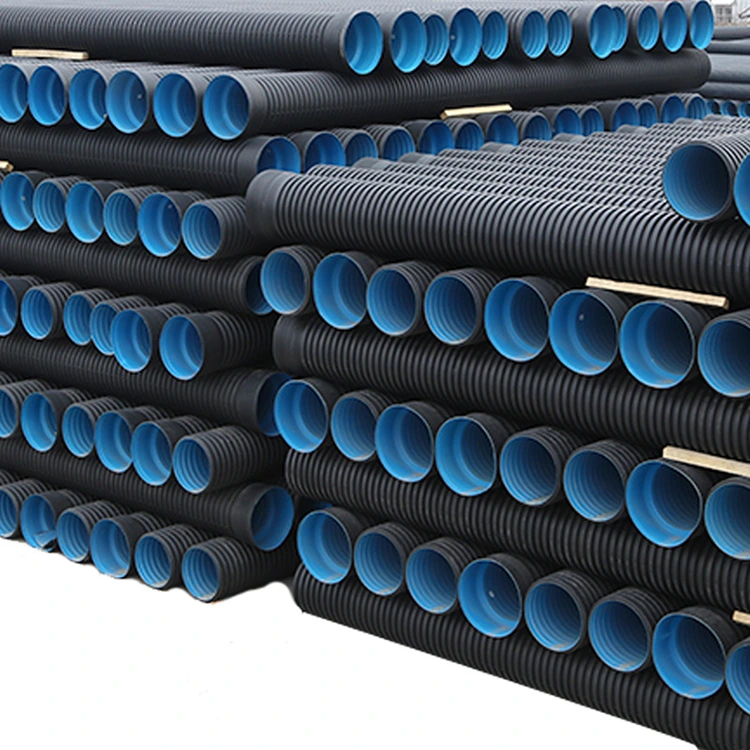

East Boom® is a HDPE Wire Conduit Power Protection Pipe factory in China, produce wholesale HDPE cable ducts that meet international ISO standards. Our durable HDPE cable protection pipes’s service life over 50 years.Email us now for a price list and OEM/ODM services!PPR Male Adaptor

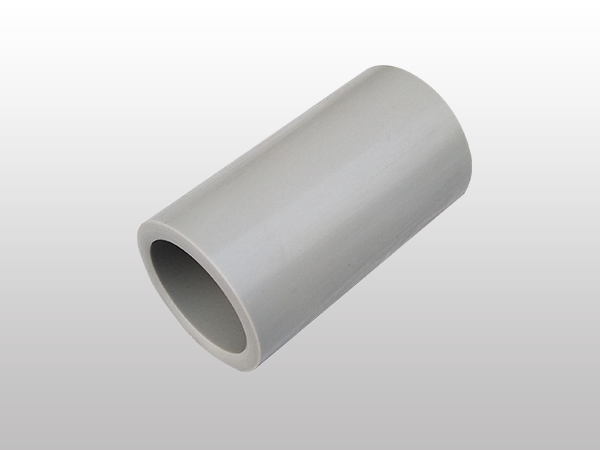

The PPR male adaptor is a critical component in water supply systems, enabling secure connections between PPR piping and threaded metal fittings. Designed for reliability, corrosion resistance, and high-temperature endurance, this adaptor supports long-term performance in both residential and industrial applications.PPR water pipe short clamp

EASTBOOM® manufactures PPR water pipe short clamp in China, offering modern clamping solutions. We provide high-quality, compact, and durable clips for plumbing, HVAC, and industrial applications. Request a custom quote today.PERT Pipes

East Boom® is a China Polyethylene of Raised Temperature Resistance Pipe factory, our products are widely used in floor heating and hot water systems. We can offer low-price PERT Pipes options, along with fast quotations.PVC Female Tee

Eastboom®'s PVC female tee is a pipe fitting made of polyvinyl chloride with at least one female thread in three ports, connecting three pipes at a 90-degree angle. Eastboom®'s tees are corrosion-resistant, lightweight, and easy to install, and are used in piping systems in multiple scenarios